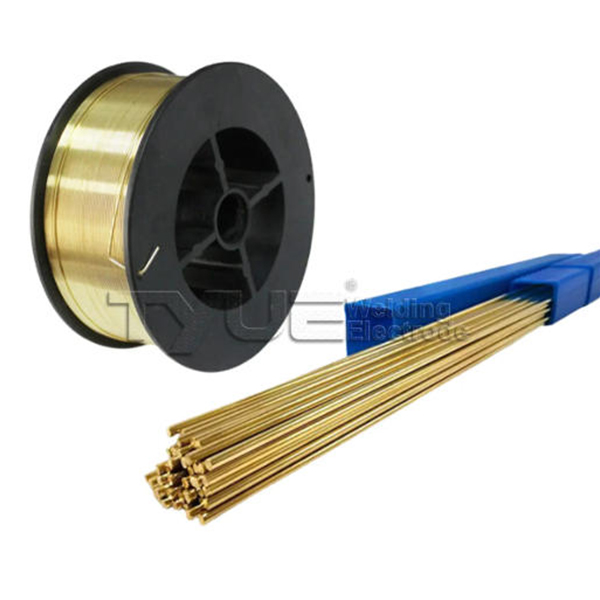

IUcingo lokuWelda lweCopper AlloyIhlelwe phantsi kweenkcukacha ze-AWS ERCu imele isinyithi esikhethekileyo sokuzalisa esenzelwe iinkqubo zokudibanisa ezikumgangatho ophezulu. Le ntambo ye-copper alloy eyenziwe nge-deoxidized yenzelwe ukudala iidiphozithi ze-weld ezixineneyo nezivakalayo ezinombane ophezulu. Njengohlobo oluthile lwe-Copper Alloy Welding Wire, ifanelekile ukusetyenziswa kwiinkqubo ze-welding ezikhuselweyo yigesi, i-TIG kunye ne-MIG welding, nto leyo eyenza ukuba ibe yi-joining kunye ne-overfacing applications ezibalulekileyo apho kufuneka khona iimpawu ze-copper.

Ulwakhiwo lweekhemikhali lwale Copper Alloy Welding Wire luyilwe ukuze lubonelele ngokusebenza kakuhle ngexesha lenkqubo yokuwelda. Izinto ezisusa ioksijini kwi-alloy zithintela ngempumelelo ukwakheka kwe-porosity kwisinyithi se-weld, ziqinisekisa ukuba iidipozithi ezivelayo ziqinile kwaye zithembekile. Olu hlobo lukhethekileyo lweCopper Alloy Welding Wire luhlala luphantsi kodidi lweentambo zokuwelda zebrass, lubonelela ngeempawu ezintle zokubopha xa udibanisa ii-alloys zebrass kwaye luququzelela ukulungiswa kwezinto ezahlukeneyo ezisekwe kubhedu.

Olu hlulo lweUcingo lokuWelda lweCopper Alloyibonisa iipropati ezithile zomzimba ezichaza iiparameter zayo zokusebenza. Ineqondo lobushushu le-solidus elimalunga ne-1020°C kunye nobushushu be-liquidius ye-1050°C, imisela uluhlu lwayo lokunyibilika ukuze kuphuhliswe inkqubo yokuwelda ngokufanelekileyo. Ngoxinano lwe-8.9 kg/dm³, le Copper Alloy Welding Wire iphathwa ngendlela eqikelelweyo ngexesha lokusebenza kwe-welding okuzenzakalelayo kunye nokusebenza ngesandla, inika ukutyibilika okuzinzileyo kunye neempawu ze-arc.

Ii-welds ezenziwe ngolu cingo lwe-copper alloy welding zibonisa iimpawu ezintle zoomatshini, zihlangabezana neemfuno ezingqongqo zokusetyenziswa. Amandla okuxinana kwentsimbi ye-weld aqhele ukuba phakathi kwe-210-220 N/mm², enobude obuyi-30% ukuya kwi-40%, nto leyo ebonisa ukuba i-ductility ilungile. Ubunzima beBrinell bumalunga ne-60 HB, nto leyo eqinisekisa ukuhambelana okuhle phakathi kwe-weld kunye nezinto ezisisiseko zobhedu, kwaye inika amandla aneleyo kwizicelo ezininzi zoshishino apho izinto zobhedu zimelana noxinzelelo lokusebenza.

I-ERCuucingo lokuwelda lwe-alloy yobheduidibanisa umbane ogqwesileyo, amandla oomatshini, kunye nokudityaniswa. Ezi mpawu zenza olu hlobo lwentambo yokuwelda ye-alloy yobhedu lubaluleke kakhulu kwiinkalo ezifana nokuveliswa kombane, iinkqubo zemibhobho, kunye nokugcinwa kwemizi-mveliso, apho ubhedu oluthembekileyo lokudibanisa ubhedu lubaluleke kakhulu. Iimpawu zayo eziphezulu zomzimba nezoomatshini ziqinisekisa iziphumo zokuwelda ezihambelanayo kwiintlobo ngeentlobo zezicelo zokuwelda kumashishini okuvelisa nokulungisa.

Ixesha leposi: Novemba-11-2025