Ukuwelda kwe-TIG kwaqalwa eMelika (e-USA) ngo-1936, okwaziwa ngokuba yi-Argon arc welding. I-TIG ivumela ukuba kuveliswe amajoyinti awelding asemgangathweni ophezulu ngezixhobo zegesi ezingangenisi mandla ezineziphumo ezicocekileyo zokuwelda. Le ndlela yokuwelda yinkqubo yokuwelda eyenzelwe zonke izinto ezisetyenzisiweyo, ubukhulu bodonga, kunye neendawo zokuwelda.

Iingenelo zale ndlela yokuwelda kukuba ayivelisi manzi amaninzi kwaye ingcolisa kancinci ngelixa iqinisekisa ukuba ijoyinti eweldiweyo ikumgangatho ophezulu ukuba isetyenziswa ngokufanelekileyo. Ukondla izinto ezisetyenziswayo zokuwelda kunye nomsinga azinxibelelananga, ngoko ke oku kwenza i-TIG ifaneleke kwiindlela zokuwelda iingcambu kunye nokuwelda okukwindawo ethile.

Nangona kunjalo, i-TIG welding ifuna umntu oqeqeshiweyo ukuze ayisebenzise ngesandla esinobuchule nolwazi lokusetyenziswa ngokuchanekileyo kwe-voltage kunye ne-amperage. Ezo zinto ziya kuxhasa iziphumo ze-TIG welding ezicocekileyo nezingcono. Kwaye ndicinga ukuba le yeyona ngongoma ibangela iingxaki ze-TIG welding.

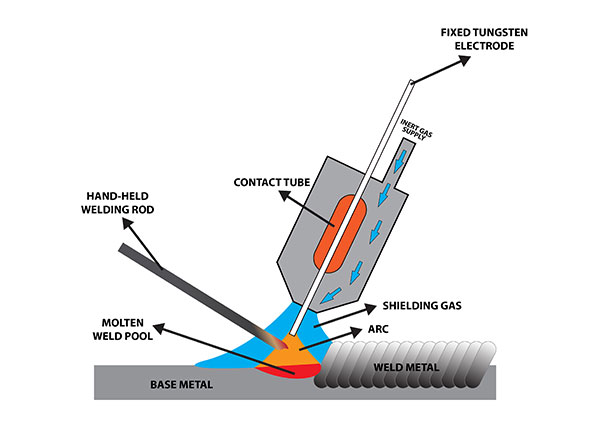

Njengoko ubona kuloo mfanekiso, emva kokuba ucinezele iswitshi yetotshi, igesi iqala ukuhamba. Xa incam yetotshi ichukumisa umphezulu wesinyithi, kwenzeka i-short circuit. Ngenxa yobuninzi bombane kwincam yetotshi, isinyithi siqala ukufuma kwindawo esidibana kuyo kwaye i-arc iyavutha, ewe, igqunywe yigesi yokukhusela.

Ukubeka uxinzelelo lwegesi/ukuhamba kwamanzi

Izinga lokuhamba kwegesi likwi-l/min kwaye lixhomekeke kubukhulu bechibi lokuwelda, ububanzi be-electrode, ububanzi be-nozzle yegesi, umgama we-nozzle kumphezulu wesinyithi, ukuhamba komoya okujikelezileyo kunye nohlobo lwegesi yokukhusela.

Umthetho olula kukuba iilitha ezi-5 ukuya kwezili-10 zegesi yokukhusela kufuneka zongezwe kwi-argon njengegesi yokukhusela kunye nobubanzi be-tungsten electrode esetyenziswa kakhulu, ngesantya se-1 ukuya kwi-4 mm ngomzuzu.

INDAWO YETOSHI

Njengakwi-MIG Welding, indawo yetotshi, xa usebenzisa indlela ye-TIG Welding, nayo ibaluleke kakhulu. Indawo yetotshi kunye nentonga ye-electrode ziya kuchaphazela iziphumo ezahlukeneyo ze-welding.

I-Electrode ngokwayo ikwayinto esetyenziswayo xa kudityaniswa i-TIG. Izinto ezisetyenziswayo xa kudityaniswa i-welding zihlala zikhethwa ngendlela efanayo nohlobo lwesinyithi. Nangona kunjalo, ngenxa yezizathu ze-metallurgical, kuyimfuneko ukuba izinto ezisetyenziswayo xa kudityaniswa isinyithi zitshintshe kwisinyithi esiyintloko xa kusetyenziswa izinto ezithile ezidityanisiweyo.

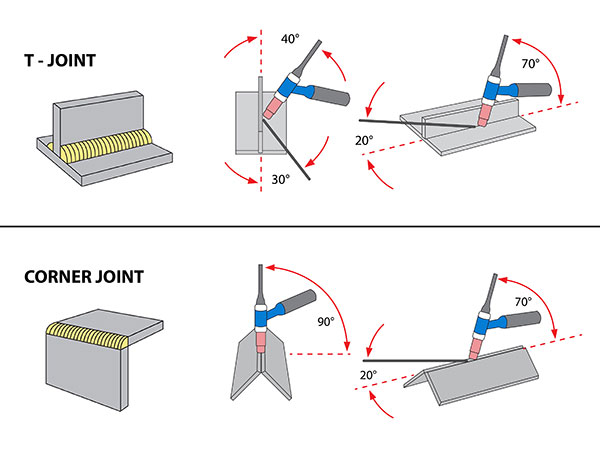

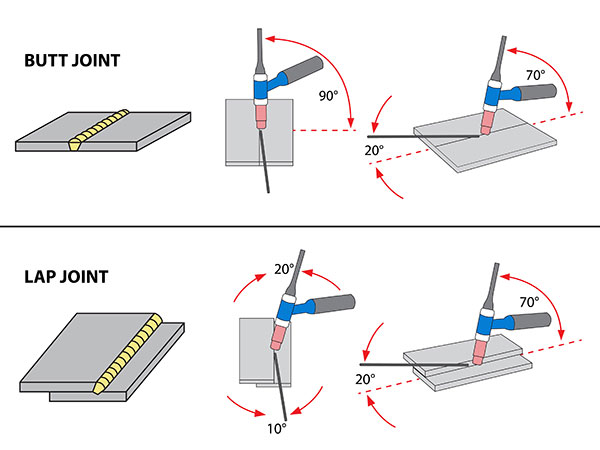

Buyela kwindawo yetotshi. Ungafaka iindawo ezahlukeneyo zetotshi yeTIG kunye nentonga ye-electrode ngelixa udibanisa iindawo ezahlukeneyo zentsimbi. Ngoko ke indawo yetotshi ixhomekeke kuhlobo lweendawo zentsimbi. Nditsho ukuba kukho iindawo ezine zentsimbi ezisisiseko ezifana nezi:

I-T- Joint

Indawo edibeneyo yekona

I-Butt Joint

I-Lap Joint

Ungazisebenzisa ezinye zezi zikhundla zetotshi kwimisebenzi ofuna ukuyigqiba. Kwaye xa uqhelene neendlela ezahlukeneyo zokuwelda iijoyinti zesinyithi, ungafunda ngeeparameter zokuwelda.

IIPARAMETHA ZOKUWELDA

Xa ukhetha iiparameter zokuwelda, kufuneka kuqatshelwe ukuba kuphela umbane obekwe kumatshini wokuwelda. I-voltage imiselwa bubude be-arc, obugcinwa ngumwelda.

Ngoko ke, ubude obukhulu be-arc bufuna i-voltage ephezulu ye-arc. Umsinga we-welding we-45 amperage nge-mm nganye yobukhulu besinyithi usetyenziswa njengexabiso lesalathiso somsinga owaneleyo we-welding steel ukuze ingene ngokupheleleyo.

IPOSIWE NGU-WENZHOU TIANYU ELECTRONIC CO., LTD.

Ixesha lokuthumela: Juni-12-2023