I-TIG welding yaqalwa okokuqala eMelika (USA) ngo-1936, eyaziwa ngokuba yiArgon arc welding.I-TIG ivumela ukuba udidi oluphezulu oludityanisiweyo luveliswe ngenkxaso yegesi engasebenziyo eneziphumo ezicocekileyo ze-welding.Le ndlela ye-welding yinkqubo ye-welding yenjongo yonke malunga nezinto ezisetyenzisiweyo, ubukhulu bodonga, kunye nezikhundla ze-welding.

Iingenelo zale ndlela yokuwelda azivelisi nasiphi na isitshizi kunye nezingcolisi ezimbalwa ngelixa ziqinisekisa udidi oludityanisiweyo oluphezulu ukuba lusetyenziswe ngokufanelekileyo.Ukutya kwe-welding consumables kunye nekhoyo ngoku ayidityaniswanga, ngoko ke oku kwenza i-TIG ilungele ukupasa kweengcambu kunye ne-positional welding.

Nangona kunjalo, i-TIG welding idinga i-welder eqeqeshwe kakuhle ukuze isetyenziswe ngesandla esinobuchule kunye nolwazi lokusetyenziswa okuchanekileyo kwamandla ombane kunye ne-amperage.Abo baya kuxhasa isiphumo se-TIG esicocekileyo nesilungileyo.Kwaye ndicinga ukuba ezi ziyingongoma ye-TIG ye-welding disadvantages.

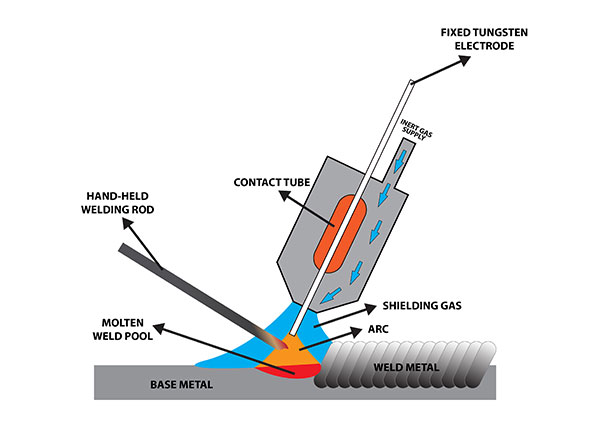

Njengoko ubona kulo mfanekiso, emva kokuba ucofe iswitshi yetotshi igesi iqalisa ukuhamba.Kwaye xa incam yetotshi ichukumisa ubuso besinyithi, isiphaluka esifutshane senzeke.ngenxa yoxinaniso oluphezulu lwangoku kwincam yetotshi, intsimbi iqalisa ukunuka kwindawo yoqhagamshelwano kwaye i-arc iyavutha, ngokuqinisekileyo, igqunywe yirhasi ekhuselayo.

UKUBEKA UXINZELELO LWEGAS / UKUHAMBA

Umyinge wokuhamba kwerhasi ukwi-l/min kwaye ixhomekeke kubungakanani bechibi le-weld, idiameter ye-electrode, idayamitha yombhobho werhasi, umgama wombhobho kumphezulu wesinyithi, ukuhamba komoya okujikelezileyo kunye nohlobo lwerhasi ekhuselayo.

Umgaqo olula kukuba i-5 ukuya kwi-10 ilitha yegesi yokukhusela kufuneka yongezwe kwi-argon njengegesi yokukhusela kunye neyona ndlela isetyenziswa kakhulu kwi-electrode diameters ye-tungsten, kwinqanaba le-1 ukuya kwi-4 mm ngomzuzu.

IMEKO YETOSHI

Njengoko kwi-MIG Welding, indawo yetotshi, xa usebenzisa indlela ye-TIG Welding, nayo ibaluleke kakhulu.Isikhundla setotshi kunye nentonga ye-electrode iya kuchaphazela iziphumo ze-welding ezahlukeneyo.

I-Electrode ngokwayo nayo i-welding consumable esetyenziswa ngexesha le-TIG welding.I-welding consumables idla ngokukhethwa ngendlela efanayo nohlobo lwetsimbi.Nangona kunjalo, ngenxa yezizathu ze-metallurgical, kuyimfuneko ukuba i-welding consumables iphambuke kwintsimbi yomzali xa kusetyenziswa izinto ezithile zokudibanisa.

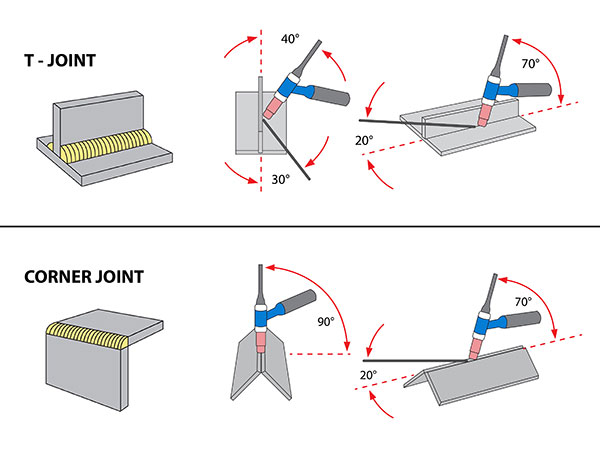

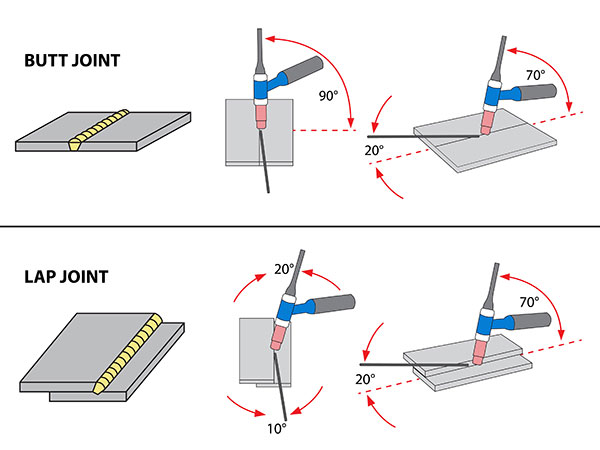

Buyela kwindawo yetotshi.Unokufaka izithuba ezahlukeneyo zetotshi ye-TIG kunye nentonga ye-electrode ngelixa udibanisa amajoyina esinyithi ahlukeneyo.Ngoko indawo yetotshi ixhomekeke kuhlobo lwamalungu esinyithi.Ndithetha ukuba kukho iindawo ezi-4 zentsimbi ezisisiseko ezifana nezi:

T- Joint

IKona edibeneyo

I-Butt Joint

Lap Joint

Unokufaka ezinye zezi zithuba zetotshi kwimisebenzi ofuna ukuyigqiba.Kwaye xa uqhelana neendawo ezahlukeneyo zetsimbi ezidibanisa itotshi, ngoko unokufunda malunga neeparitha ze-welding.

I-WELDING PARAMETERS

Xa ukhetha i-welding parameters, kufuneka kuqatshelwe ukuba kuphela okwangoku kusekwe kumatshini we-welding.I-voltage inqunywe ngubude be-arc, obugcinwa ngu-welder.

Ke ngoko, ubude be-arc enkulu bufuna amandla ombane aphezulu e-arc.I-welding current ye-45 amperage per mm yobunzima betsimbi isetyenziswe njengexabiso lereferensi yangoku eyaneleyo yentsimbi ye-welding ukuze ingene ngokupheleleyo.

ITHUNYELWE NGUWENZHOU TIANYU ELECTRONIC CO., LTD.

Ixesha lokuposa: Jun-12-2023