I-ERNiFe-CI isetyenziselwa i-welding yentsimbi.Le ntsimbi yokuzalisa isetyenziswa kakhulu ukoleka imiqulu yentsimbi.Ikwasetyenziselwa ukulungisa iicastings.Ubushushu bangaphambili kunye ne-interpass ye-175ºC (350ºF) ubuncinci bucetyiswayo ngexesha le-welding, ngaphandle apho i-weld kunye neendawo ezichatshazelwe bubushushu zinokuvelisa iintanda.

I-Ni 55 (iklasi ye-AWS ayichazwanga) yi-55% ye-Nickel wire.Umxholo ophantsi we-Nickel wenza le ngxube ibe noqoqosho ngakumbi kune-Ni 99. Iidiphozithi ze-Weld zihlala zisebenza ngomatshini, kodwa phantsi kweemeko zokuxutywa okuphezulu, ii-welds zinokuba nzima kwaye kunzima ukuzisebenzisa.Ihlala isetyenziselwa ukulungisa ii-castings ezinamacandelo anzima okanye anzima.Xa kuthelekiswa ne-Ni 99, ii-welds ezenziwe nge-55 Ni zinamandla kwaye zine-ductile ngakumbi, kwaye zinyamezela ngakumbi kwi-phosphorous ekubunjweni.Ikwanayo ne-coefficient esezantsi yokwandisa kune-Ni 99, ekhokelela ekuqhekekeni okumbalwa komgca wokudibanisa.

UHLELO LWEKHEMICAL:

| I-NickelNi45.0-60.0% | IronFebalance | I-SiliconSimax 4.0% | IManganeseMn2.5% | ICopperCu2.5% | CarbonCmax 2.0% | iAluminiyamAlmax 1.0% |

IIPROPATI ZOOMATSHINI:

| Amandla okuqina Rm (MPa) | Amandla esivuno Rp0.2 (MPa) | Elongation A % |

| imiz.393-579 (57-84 psi) | 296-434 (40-64 psi) | 6-13 |

IIFOMU ZEMVELISO:

| Imveliso | Ububanzi, mm | Ubude, mm |

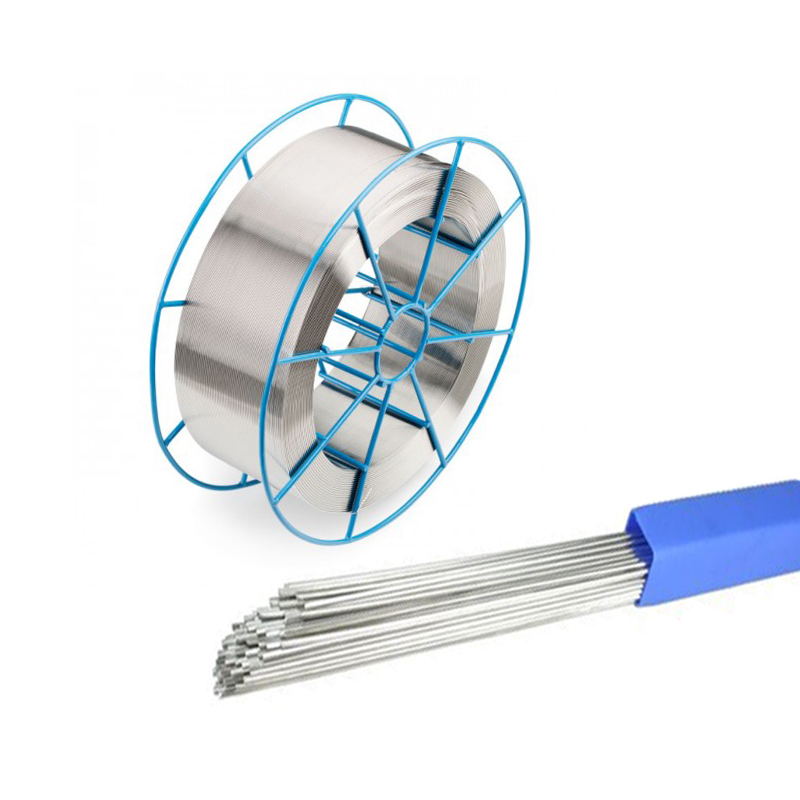

| Ucingo lwe-MIG/GMAW welding | 0.8, 1.0, 1.2, 1.6, 2.0, 2.4, 2.5, 3.2 | - |

| Iinduku ze-TIG/GTAW zokuwelda | 2.0, 2.5, 3.2, 4.0, 5.0 | 915 – 1000 |

| Ucingo lwe-SAW welding | 2.0, 2.4, 3.2, 4.0, 5.0 | - |

| Electrode core wire | 2.0, 2.5, 3.20, 3.25, 4.0, 5.0 | 250, 300, 350, 400, 450, 500 |

I-Binary Nickel-Iron (Ni-Fe) kunye ne-Ni esekelwe kwii-alloys ze-welding eziyinkimbinkimbi zibonelelwa ngentonga ye-welding kunye neengcingo ngobude obuqhelekileyo okanye ubude ukuya kwisicelo sabathengi.Kwiimeko zenkonzo eqhelekileyo, ukwakheka kweekhemikhali ziyafumaneka kwimixholo eyahlukeneyo yeNi ngokweyona migangatho yaseMelika naseYurophu.