Ukuwelda kweNsimbi EngagqwaliyoI-electrode

G207NiMo

GB/T E410NiMo -15

I-AWS E410NiMo -15

Inkcazo: I-G207NiMo yi-electrode yentsimbi engagqwaliyo ye-martensitic ene-hydrogen sodium ephantsi. Sebenzisa i-DCEP (i-electrode yangoku ngqo) kwaye ingakwazi ukutshixwa kuzo zonke iindawo. Umaleko womphezulu uneempawu ezilungileyo zokulwa nokuguguleka kwesanti kunye nokuguguleka kwesanti. Inkqubo yokutshixwa komphezulu ilula, akukho mfuneko yokufudumeza ngaphambi kokutshixwa, akukho nyango lobushushu olufunekayo emva kokutshixwa, kwaye umaleko womphezulu ungatshixwa ngomatshini.

Ukusetyenziswa: Isetyenziswa kakhulu ekulungiseni ukuwelda kwezinto ezisetyenziswa kwisinyithi ze-0Cr13Ni4Mo, ukulungiswa kweendawo ezihambayo zamanzi emva kokuguguleka kwe-cavitation, kunye nokuwelda iindawo zesakhiwo sento efanayo.

Ukwakheka kweekhemikhali zesinyithi esijiyiweyo (%):

| C | Mn | Si | Cr | Ni | Mo | S | P |

| ≤0. 06 | ≤1.0 | ≤0.90 | 11.0 ~ 12.5 | 4.0 ~ 5.0 | 0.40 ~ 0.70 | ≤0.03 | ≤0.04 |

Iimpawu zoomatshini zesinyithi esijijekileyo:

| Into yovavanyo | Tensile strength I-Mpa | Ukwandiswa % |

| Iqinisekisiwe | ≥760 | ≥15 |

I-current ecetyiswayo:

| Ububanzi bentonga (mm) | 3.2 | 4.0 | 5.0 |

| Ukuwelda kwangoku (A) | 80 ~ 120 | 120 ~ 160 | 150 ~ 190 |

Isaziso:

1. I-electrode mayibhakwe iyure e-1 malunga ne-300℃ ngaphambi kokuba isebenze nge-welding;

2. Kubalulekile ukucoca umhlwa, isikali seoyile, amanzi, kunye nokungcola kwiindawo zokuwelda ngaphambi kokuba uwelda.

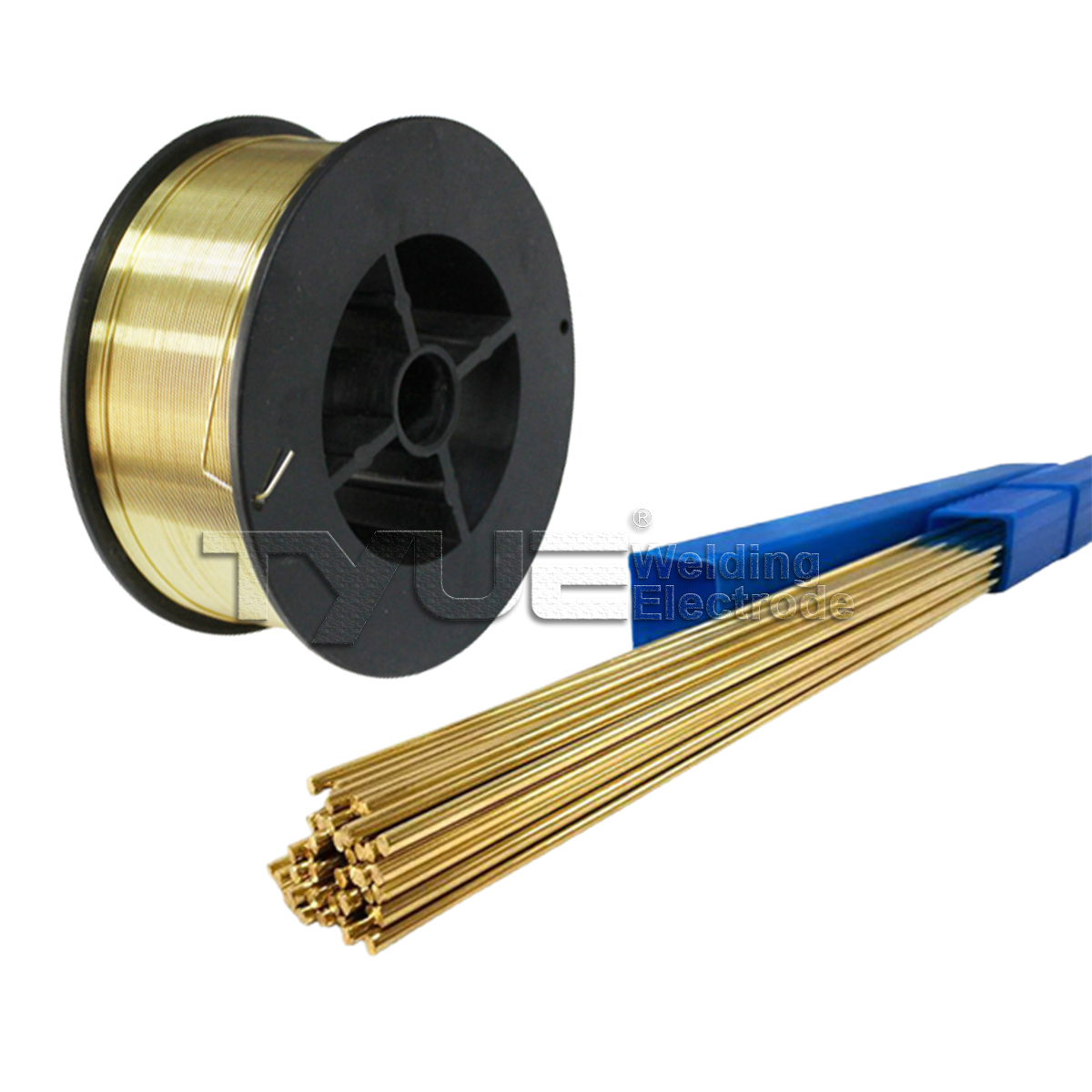

I-Wenzhou Tianyu Electronic Co., Ltd. yasungulwa ngo-2000. Besibandakanyeka kwimveliso yei-electrode yokuweldas, iintonga zokuwelda, kunye nezinto ezisetyenziswayo zokuwelda iminyaka engaphezu kwama-20. Iimveliso zethu eziphambili ziquka intsimbi engagqwaliyoi-electrode yokuweldaii-electrode zokuwelda zentsimbi yekhabhoni, ii-electrode zokuwelda ze-alloy ephantsi, ii-electrode zokuwelda eziphezu komhlaba, ii-electrode zokuwelda ze-nickel kunye ne-cobalt alloy, ii-wire welding zentsimbi emild kunye ne-low alloy, ii-wire welding zentsimbi engatyiwayo, ii-wire ze-flux cored ezikhuselwe yigesi, ii-wire welding ze-aluminium, i-submerged arc welding. ii-wire, ii-wire welding ze-nickel kunye ne-cobalt alloy, ii-wire welding ze-brass, ii-wire welding ze-TIG kunye ne-MIG, ii-electrode ze-tungsten, ii-electrode ze-carbon gouging, kunye nezinye izixhobo zokuwelda kunye nezinto ezisetyenziswayo.