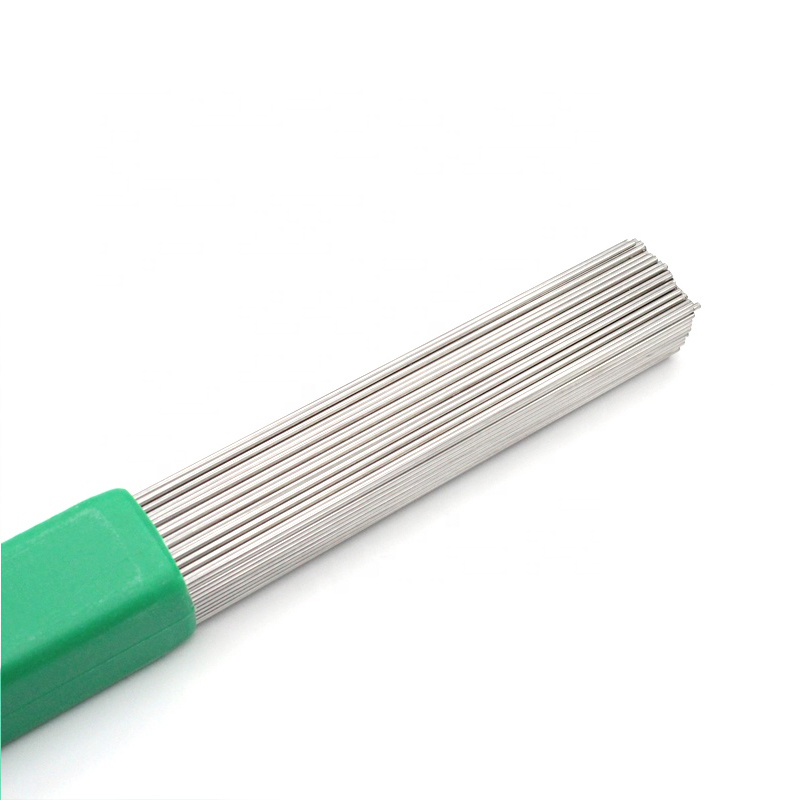

I-ER4043 yintambo yokuwelda ye-aluminium yohlobo oluqhelekileyo. Yenye yezona alloys zokwelda kunye nebrazing ezindala nezisetyenziswa kakhulu. Le alloy ye-aluminium iqulethe izongezo ze-silicon, ezibangela ukunyibilika okuphuculweyo (isenzo sokumanzisa) kwedama lokuwelda kwaye ikwavelisa i-weld engachukumisi kakhulu xa iqhekeka. Ukugqitywa kwayo kwe-weld eqaqambileyo kwenza ukuba ibe lukhetho oludumileyo lwabawelda. I-ER4043 ingasetyenziselwa ukuwelda iintlobo ezahlukeneyo ze-aluminium.

Izicelo eziqhelekileyo: ucingo lokugcwalisa i-welding; ucingo olutshizayo kunye nolwe-metalizing olutshizwayo

| Iklasi ye-AWS: ER4043 | Isiqinisekiso: AWS A5.10/ A5.10M:1999 |

| I-alloy: ER4043 | I-AWS/ASME SFA A5.10 |

| Indawo yokuWelda: F, V, OH, H | Okwangoku: I-DCEP-GMAW I-AC-GTAW |

Iipropati eziqhelekileyo (njengoko zitshixiwe)

| Ukuqhuba: | 42% IACS (-12) |

| Amandla okuThamba, kpsi: | 29 |

| Umbala: | Ngwevu |

| Indawo yokunyibilika | 1170⁰F | Ukuqina | 1065⁰F | Uxinano | 0.097 lbs/cu Ngaphakathi. |

I-Cystemi yeWire eqhelekileyo ngokwe-AWS A5.10 (amaxabiso alinganayo aphezulu)

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Okunye | Al | ||||||

| 4.5-6.0 | 0.8 | 0.30 | 0.05 | 0.05 | 0.10 | 0.20 | 0.15 | Intsalela | ||||||

| Iiparameters zeWelding eziqhelekileyo | ||||||||||||||

| Ububanzi | Inkqubo | I-Volt | Ii-Amps | Igesi | ||||||||||

| in | (mm) | |||||||||||||

| .030 | (.8) | I-GMAW | 15-24 | 60-175 | I-Argon (cfh) | |||||||||

| .035 | (.9) | I-GMAW | 15-27 | 70-185 | I-Argon (cfh) | |||||||||

| 3/64” | (1.2) | I-GMAW | 20-29 | 125-260 | I-Argon (cfh) | |||||||||

| 1/16” | (1.6) | I-GMAW | 24-30 | 170-300 | I-Argon (cfh) | |||||||||

| 3/32” | (2.4) | I-GMAW | 26-31 | 275-400 | I-Argon (cfh) | |||||||||

| Ububanzi | Inkqubo | I-Volt | Ii-Amps | Igesi | ||||||||||

| in | (mm) | |||||||||||||

| 1/16” | (1.6) | I-GTAW | 15 | 60-80 | I-Argon (cfh) | |||||||||

| 3/32” | (2.4) | I-GTAW | 15 | 125-160 | I-Argon (cfh) | |||||||||

| 1/8” | (3.2) | I-GTAW | 15 | 190-220 | I-Argon (cfh) | |||||||||

| 5/32” | (4.0) | I-GTAW | 15 | 200-300 | I-Argon (cfh) | |||||||||

| 3/16” | (4.8) | I-GTAW | 15-20 | 330-380 | I-Argon (cfh) | |||||||||

I-Wenzhou Tianyu Electronic Co., Ltd. yasekwa ngo-2000. Besisenza ushishino lokuvelisa ii-electrode zokuwelda, iintonga zokuwelda, kunye nezinto ezisetyenziswayo zokuwelda kangangeminyaka engaphezu kwama-20.

Iimveliso zethu eziphambili ziquka ii-electrode zokuwelda zentsimbi engagqwaliyo, ii-electrode zokuwelda zentsimbi yekhabhoni, ii-electrode zokuwelda ze-alloy ephantsi, ii-electrode zokuwelda eziphezu komhlaba, ii-electrode zokuwelda ze-nickel kunye ne-cobalt alloy, ii-wire welding zentsimbi emild kunye ne-low alloy, ii-wire welding zentsimbi engagqwaliyo, ii-wire ze-flux cored ezikhuselwe yigesi, ii-wire welding ze-aluminium, ii-inferiored arc welding. ii-wire, ii-wire welding ze-nickel kunye ne-cobalt alloy, ii-wire welding ze-brass welding, ii-wire welding ze-TIG kunye ne-MIG, ii-electrode ze-tungsten, ii-electrode ze-carbon gouging, kunye nezinye izixhobo zokuwelda kunye nezinto ezisetyenziswayo.