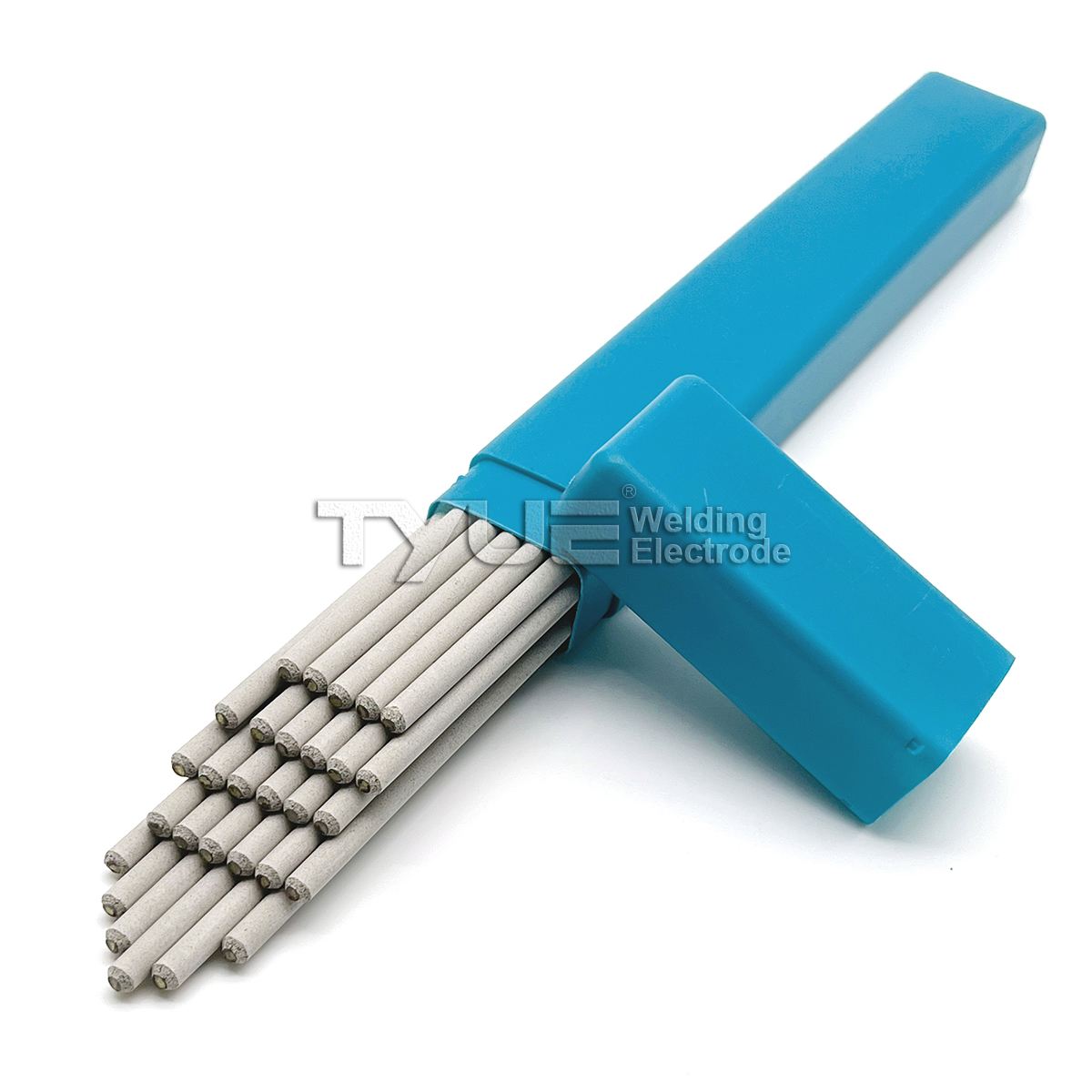

I-Electrode yeWelding yentsimbi ephantsi ye-Alloy

J555G

GB/T E5510-G

I-AWS A5.5 E8010-G

Inkcazo: I-J555G yi-electrode esezantsi ethe nkqo ene-cellulose ephezulu ene-sodium. Sebenzisa i-DCEP (i-electrode yangoku ethe nkqo). Ifanelekile kwi-welding ethe nkqo ezantsi ethe nkqo yomthungo ojikelezayo kwindawo yombhobho. Ingadityaniswa kwelinye icala kwaye yenziwe kumacala omabini, kwaye isantya sokudityaniswa siyakhawuleza.

Ukusetyenziswa: Isetyenziselwa ukuwelda imibhobho eyahlukeneyo yentsimbi eneentsimbi eziphantsi.

Ukwakheka kweekhemikhali zesinyithi esijiyiweyo (%):

| C | Mn | Si | S | P |

| ≤0.20 | ≥1.00 | ≤0.50 | ≤0.035 | ≤0.035 |

熔敷金属力学性能 Iimpawu zobuxhakaxhaka bentsimbi yeweld:

| Into yovavanyo | Tensile strength I-Mpa | Unikeze Amandla I-Mpa | Ukwandiswa % | Ixabiso lempembelelo (J) -30℃ |

| Iqinisekisiwe | ≥540 | ≥440 | ≥17 | ≥27 |

Ukuhlolwa kwe-X-ray: Ibanga lesi-II

I-current ecetyiswayo:

| (mm) Ububanzi bentonga | 2.5 | 3.2 | 4.0 | 5.0 |

| (A) Ukuwelda kwangoku | 40 ~ 70 | 70 ~ 110 | 110 ~ 160 | 160 ~ 190 |

Isaziso:

1. Khulula intonga yokuwelda ngaphambi kokuba uyisebenzise, kwaye uyisebenzise kangangoko unako emva kokuyivula;

2. Ngokubanzi, akukho mfuneko yokuyomisa kwakhona ngaphambi kokuyidibanisa, kwaye ingomiswa kwi-70~90°C kangangeyure e-1 xa ifumile.

I-Wenzhou Tianyu Electronic Co., Ltd. yasungulwa ngo-2000. Besibandakanyeka kwimveliso yei-electrode yokuweldas, iintonga zokuwelda, kunye nezinto ezisetyenziswayo zokuwelda kangangeminyaka engaphezu kwama-20.

Iimveliso zethu eziphambili ziquka intsimbi engagqwaliyoi-electrode yokuweldas, ii-electrode zokuwelda zentsimbi yekhabhoni,ii-electrode zokuwelda ze-alloy ephantsi, ii-electrode zokuwelda eziphezu komhlaba, ii-electrode zokuwelda ze-nickel kunye ne-cobalt alloy, ii-wire welding zentsimbi ethambileyo kunye ne-low alloy, ii-wire welding zentsimbi engatyiwayo, ii-wire ze-flux ezikhuselwe yigesi, ii-wire welding ze-aluminium, i-inferiored arc welding. ii-wire, ii-wire welding ze-nickel kunye ne-cobalt alloy, ii-wire welding zebrass, ii-wire welding ze-TIG kunye ne-MIG, ii-electrode ze-tungsten, ii-electrode ze-carbon gouging, kunye nezinye izixhobo zokuwelda kunye nezinto ezisetyenziswayo.