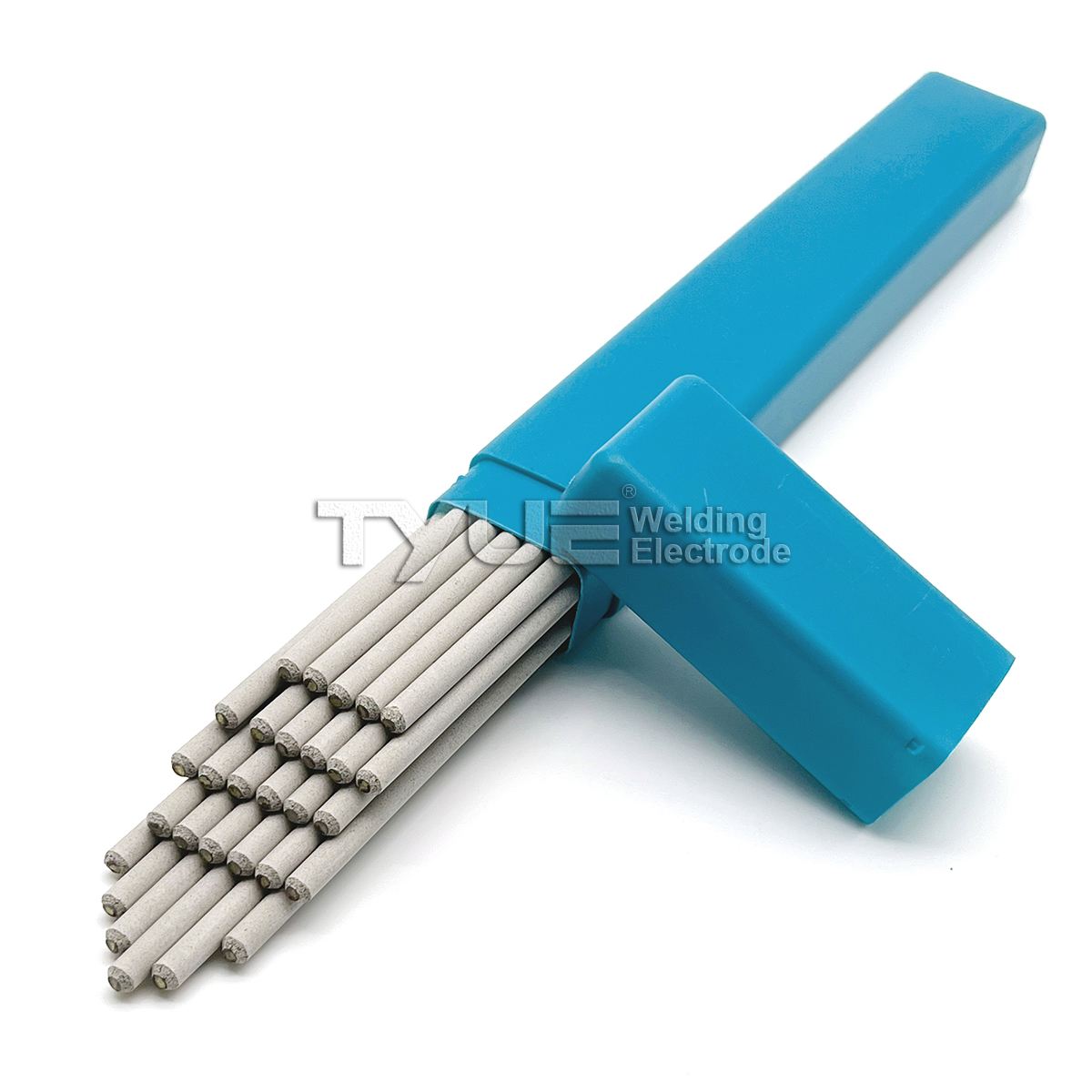

I-Alloy ephantsi ye-Steel Welding Electrode

I-J506NiMA, J507NiMA

I-GB/T E5016-G E5015-G

AWS E7018-G E7015-G

Inkcazo: I-J506NiMA kunye ne-J507NiMA i-electrode yensimbi ephantsi kwe-hydrogen-coated i-ultra-low-coated low-alloy steel.Intsimbi ediphozithiweyo ineplastiki egqwesileyo, ukuqina kobushushu obuphantsi kunye nokumelana nokuqhekeka, kwaye inokudityaniswa kuzo zonke izikhundla.Ukwaleka kuxhathisa ukufunxa ukufuma.Emva kokuba i-electrode ibhakwe kwi-400 ° C x 1h kwaye ipakishwe kwindawo enomswakama ohambelanayo ≥ 80% kwiiyure ze-4, umxholo wokufuma we-coating usahlangabezana neemfuno zokusetyenziswa.

Isicelo: Isetyenziselwa ukuwelda amaqonga e-oyile, iinqanawa, iinqanawa zoxinzelelo, kunye nezinye izinto ezenziweyo.carbon steel kunye nentsimbi ephantsi ye-alloy.

Ukwakhiwa kweekhemikhali zentsimbi edibeneyo(%):

| C | Mn | Si | Ni | S | P | |

| Iqinisekisiwe | ≤0.12 | ≥1.00 | ≤0.50 | ≤0.60 | ≤0.035 | ≤0.040 |

Iimpawu zobuchwephesha bentsimbi ye-weld:

| Into yovavanyo | Tensile strength Mpa | Unikeze Amandla Mpa | Elongation % | Ixabiso lempembelelo (J) -46℃ |

| Iqinisekisiwe | ≥490 | ≥390 | ≥22 | ≥27 |

Ukusasazwa kwe-hydrogen umxholo wentsimbi egciniweyo: ≤5.0mL/100g (i-chromatography yegesi okanye indlela ye-mercury)

Isiqulatho sokufuma seengubo ze-electrode: ≤0.30%

Ukuhlolwa kwe-X-reyi: I grade

yangoku eCetyisiweyo:

| Intonga yobubanzi | 2.5 | 3.2 | 4.0 | 5.0 |

| I-Welding yangoku | 60 ~ 90 | 90 ~ 120 | 140 ~ 180 | 170 ~ 210 |

Isaziso:

1. I-electrode kufuneka ibhakwe ngeyure eli-1 kwi-350 ~ 400℃ ngaphambi kokusebenza kwe-welding;

2. Kubalulekile ukucoca umhlwa, isikali se-oyile, amanzi, kunye nokungcola kwiindawo zokuwelda phambi kokuba udibanise;

3. Sebenzisa umsebenzi omfutshane we-arc xa udibanisa.Umzila we-welding emxinwa ufanelekile.