Ucingo lweBronze lwe-AWS A5.7 ERCuSn-C Phosphor

Intshayelelo

Kucetyiswa ukuwelda ubhedu nge-Cu-Sn alloy. Kungcono ukuwelda ubhedu oludibanisa i-butt ngentsimbi. Kucetyiswa ukufudumeza kwangaphambili kwiimveliso ezinkulu, kwaye ukuwelda kwe-argon arc eshukumayo kuyacetyiswa kwi-multilayer hard facing kwintsimbi.

| Ukubekwa emgangathweni: | Uphawu lwamanani: | |

| GB/T9460-2008 | I-SCu5210 | |

| I-AWS A5.7:2007 | I-ERCuSn-C | |

| BS EN14640:2005 | I-Cu 5210 | |

| Ulwakhiwo (amaxabiso aqhelekileyo): | % | |

| I-Cu incl.ag | ibhal. | |

| Zn | 0.20 | |

| Sn | 7.00-9.00 | |

| Fe | 0.10 | |

| P | 0.10-0.35 | |

| Al | 0.01 | |

| Pb | 0.02 | |

| Ezinye zizonke | 0.50 | |

| Iimpawu ezibonakalayo zezinto: | ||

| Uxinano | Iikhilogremu/m3 | 8.8 |

| Uluhlu lokunyibilika | ℃ | 875-1025 |

| Ukuqhuba kobushushu | W/mK | 66 |

| Ukuqhuba kombane | I-Sm/mm2 | 6-8 |

| I-coefficient yokwandiswa kobushushu | 10^-6/K(20-300℃) | 18.5 |

| Ixabiso eliqhelekileyo lesinyithi esitshixiweyo: | ||

| Ukwandiswa | % | 20 |

| Tensile strength | N/mm2 | 260 |

| Umsebenzi wokuchaphazela ibha enezikhewu | J | 32 |

| Ubunzima bukaBrinell | HB 2.5/62.5 | 80 |

| Izicelo: | ||

| I-alloy ye-copper tin enobunzima obuphezulu be-tin bokudityaniswa kwe-overlay. Ifanelekile ngokukodwa ukudityaniswa kwezinto zobhedu, ezifana ne-copper, i-tin bronzes, ngakumbi ezisetyenziselwa ukudibanisa i-copper zinc alloys kunye neentsimbi. Ifanelekile ukudityaniswa kwe-cast bronzes kunye ne-oven soldering. Kwi-multilayer welding kwintsimbi, kucetyiswa ukudityaniswa kwe-pulsed arc. Kwizinto ezinkulu zomsebenzi kucetyiswa ukufudumeza kwangaphambili. | ||

| Iinto zokuzilungisa: | ||

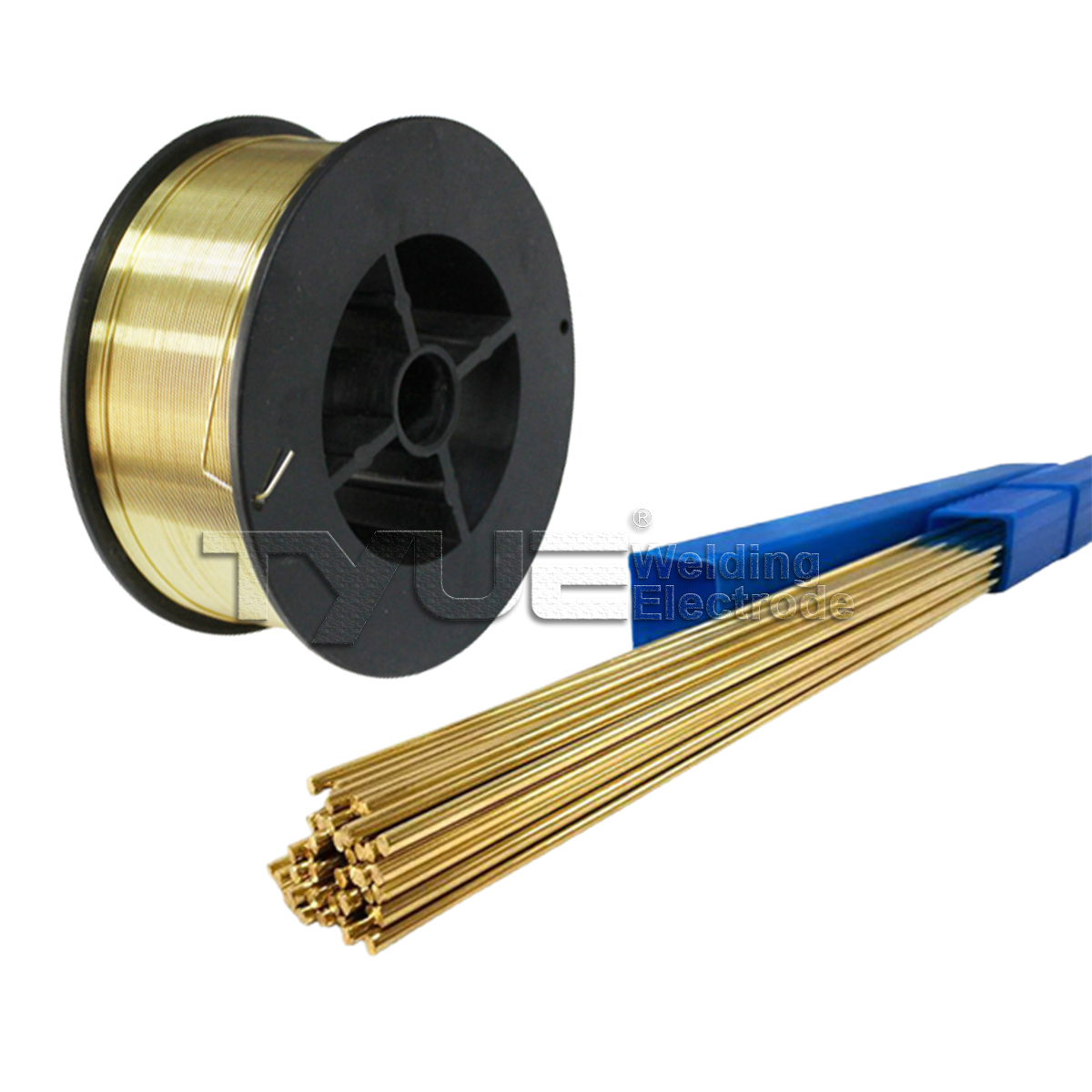

| Ububanzi: 0.64 – 0.80 – 1.00 – 1.20 – 1.60 –2.40 | ||

| IiSpools:D100,D200,D300,D760,K300,KS300 | ||

| Iintonga: 1.60 – 9.6 mm x 914/1000 mm | ||

| Ii-electrode ziyafumaneka. | ||

| Ezinye izinto zokuthambisa xa ziceliwe. | ||

I-Wenzhou Tianyu Electronic Co., Ltd. yasekwa ngo-2000. Besisenza ushishino lokuvelisa ii-electrode zokuwelda, iintonga zokuwelda, kunye nezinto ezisetyenziswayo zokuwelda kangangeminyaka engaphezu kwama-20.

Iimveliso zethu eziphambili ziquka ii-electrode zokuwelda zentsimbi engagqwaliyo, ii-electrode zokuwelda zentsimbi yekhabhoni, ii-electrode zokuwelda ze-alloy ephantsi, ii-electrode zokuwelda eziphezu komhlaba, ii-electrode zokuwelda ze-nickel kunye ne-cobalt alloy, ii-wire welding zentsimbi emild kunye ne-low alloy, ii-wire welding zentsimbi engagqwaliyo, ii-wire ze-flux cored ezikhuselwe yigesi, ii-wire welding ze-aluminium, ii-inferiored arc welding. ii-wire, ii-wire welding ze-nickel kunye ne-cobalt alloy, ii-wire welding ze-brass welding, ii-wire welding ze-TIG kunye ne-MIG, ii-electrode ze-tungsten, ii-electrode ze-carbon gouging, kunye nezinye izixhobo zokuwelda kunye nezinto ezisetyenziswayo.