| Uhlobo lwebanga lentsimbi | Intsimbi yomngundo: |

| Umgangatho |

|

| Iinkcukacha zemveliso | Ipleyiti yentsimbi, Ishiti, Ikhoyili, Ibha ethe tyaba, Ibha ejikelezileyo, Intsimbi ye-Strip, ucingo, Zonke iintlobo zezinto zokufunxa. |

| Umatshini wokucoca | Ukujika Ukusila Ukusila Ukubhoboza imingxunya enzulu: ubude obuphezulu yi-9.8 yeemitha. |

| Uluhlu lomsebenzi | Intsimbi yebha ejikelezayo: 1mm ukuya kwi-2000mm Intsimbi emile okwesikwere: 10mm ukuya kwi-1000mm Ipleyiti/iphepha lentsimbi: 0.08mm ukuya kwi-800mm Ububanzi: 10mm ukuya kwi-1500mm I-Lenth: Singabonelela ngayo nayiphi na i-lenth ngokusekelwe kwiimfuno zomthengi. Ukubumba: Iishafts ezineecala/iipayipi/iityhubhu/iislugs/iidonathi/iityhubhu/ezinye iimilo Iityhubhu: OD: φ4-410 mm, ubukhulu bodonga buqala kwi-1-35 mm. |

| Unyango lobushushu | Ukulungisa, Ukunciphisa, Ukucima, Ukuqinisa kunye nokunciphisa, Ukongeza izinongo, Ukuqinisa umphezulu, Ukulungisa iiCarburizing |

UKWAKHIWA KWEEKHEMIKHALI ZE-AWS E10015-D2 NEZINTO ZOKWENZA I-MECHANICAL:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Okunye |

IIPROPATI ZOMKHANYA:

| Iipropati | Iimeko | ||

| T (°C) | Unyango | ||

| Uxinano (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Umlinganiselo kaPoisson | 0.27-0.30 | 25 |

|

| I-Elastic Modulus (GPa) | 190-210 | 25 |

|

| Amandla okuThamba (i-Mpa) | 1158 | 25 | ioyile icinyiwe, ithambile, iqiniswe kwi-425°C |

| Amandla Okuvelisa (i-Mpa) | 1034 | ||

| Ukwandiswa (%) | 15 | ||

| Ukuncipha kweNdawo (%) | 53 | ||

| Ubunzima (HB) | 335 | 25 | ioyile icinyiwe, ithambile, iqiniswe kwi-425°C |

| Iipropati | Iimeko | ||

| T (°C) | Unyango | ||

| Ukuqhuba kwe-Thermal (W/mK) | 42.7 | 100 | |

| Ubushushu obuthile (J/kg-K) | 477 | 50-100 | |

IIPROPATHI ZOKUPHILA:

| Ubungakanani | Ixabiso | Iyunithi |

| Ukwandiswa kobushushu | 16 - 17 | e-6/K |

| Ukuqhuba kobushushu | 16 - 16 | W/mK |

| Ubushushu obuthile | 500 - 500 | I-J/kg.K |

| Ubushushu bokunyibilika | 1370 - 1400 | °C |

| Ubushushu benkonzo | 0 - 500 | °C |

| Uxinano | 8000 - 8000 | kg/m3 |

| Ukuxhathisa | 0.7 - 0.7 | Ohm.mm2/m |

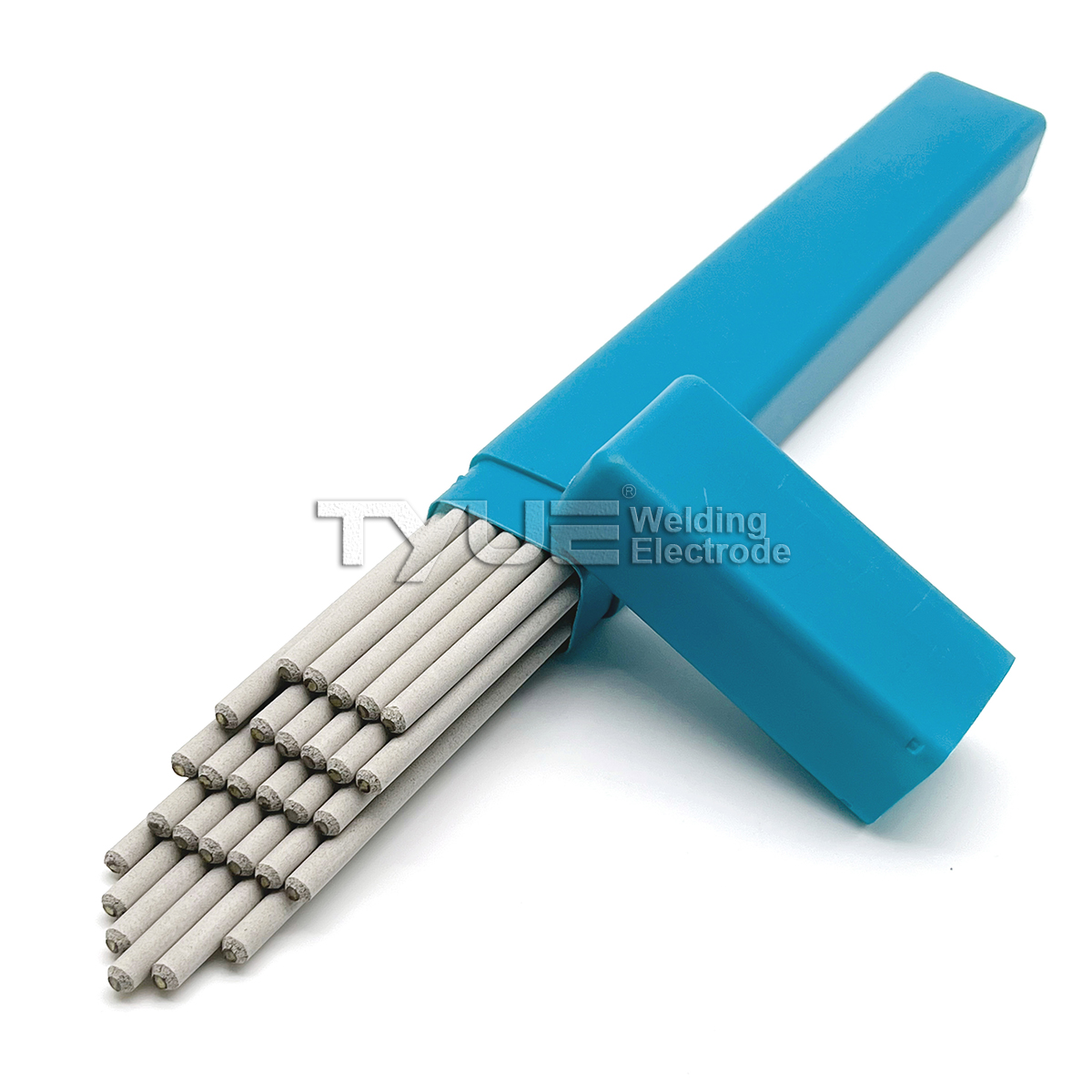

Ii-electrode zokuWelda ze-E7015-G eziphantsi zeHydrogen Sodium Coating

INKCAZELO:

Yintonga yokuwelda yentsimbi enobushushu obuphantsi ene-sodium hydrogen coating ephantsi equlethe i-nickel. Ukuwelda okukwindawo epheleleyo kungenziwa ngokudibanisa okungasemva kwe-dc. Isinyithi se-weld kwi--80°C sisenokuqina okuhle.

UKUSETYENZISWA:

Isakhiwo sentsimbi esisebenza nge-1.5Ni esidityanisiweyo -80°C.

UKWAKHIWA KWEEKHEMIKHALI ZENTSIMBI EZIGCINIWEYO:

| C | Mn | Si | Ni | S | P | |

| Umgangatho | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Uvavanyo | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

UKUSEBENZA KWEENSIMBI EZIFAKWE KWI-DENTAL:

| Amandla okuThamba (MPa) | I-Yield Strength Rel (MPa) | Ukwandiswa A (%) | Ixabiso leMpembelelo -80°C Akv (J) | |

| Umgangatho | ≥490 | ≥390 | ≥22 | ≥27 |

| Uvavanyo | 530 | 445 | 30 | 100 |

I-REFERENTIAL current (DC+):

| Ububanzi (mm) | 3.2 | 4.0 | 5.0 | |

| Ubude (mm) | 350 | 400 | 400 | |

| I-current (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Ngokutsho kwe-GB E8515-G Ihambelana ne-AWS E12015-G |

Intshayelelo: I-E12015-G luhlobo lwe-electrode yentsimbi enamandla aphantsi enee-alloy eziphantsi kunye ne-hydrogen natrium type coating. I-DCRP (i-Direct Current Reversed Polarity). Ukuwelda kwe-All-position.

Ukusetyenziswa: Isetyenziselwa ukuwelda izakhiwo zentsimbi ezinamandla aphantsi kunye namandla okutsalwa amalunga ne-830MPa.

Ukwakheka kweekhemikhali zesinyithi esigciniweyo (%)

| Ukwenziwa kweeKhemikhali | C | Mn | Si | S | P | Mo |

| Ixabiso leSiqinisekiso | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| Isiphumo Jikelele | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Iipropati zoomatshini zesinyithi esigciniweyo

| Into yoVavanyo | Rm(MPa) | Rokanye i-eLRp0.2(iMpa) | I-A(%) | KV2(J) |

| Ixabiso leSiqinisekiso | ≥830 | ≥740 | ≥12 | —(ubushushu obuqhelekileyo) |

| Isiphumo Jikelele | 860~950 | ≥750 | 12~20 | ≥27 |

Umxholo weHydrogen osasazekayo kwiMetal egciniweyo: ≤5.0ml/100g (iChromatography)

Uhlolo lweX-ray Radiographic: ⅠDegree

IMIYALELO:

1. Ii-electrode mazibhakwe phantsi kwama-350-400℃ kangangeyure ngaphambi kokuba zifakwe kwi-welding, zifakwe kwi-insulation can kwaye zifakwe ngokukhawuleza xa zifuneka.

2. Amabala akwi-weld efana nomhlwa kufuneka asuswe, kwaye i-weld kufuneka ifudunyezwe ibe malunga ne-200℃.

3. I-Weld ingathomalaliswa phantsi kwe-600-650℃ emva kokuwelda ukuze kupheliswe uxinzelelo lwangaphakathi.