| Uhlobo lwebakala lentsimbi | Intsimbi yokungunda: |

| Umgangatho |

|

| Iinkcukacha zemveliso | Ipleyiti yentsimbi, Icwecwe, Ikhoyili, Ibha eFlethi, Ibha eRound, intsimbi yomtya, ucingo, Zonke iintlobo zokubumba. |

| Mchining | Ukujika Ukugaya Ukusila Ukugrumba umngxuma onzulu: ubude bubude be-9.8 yeemitha. |

| Uluhlu lomsebenzi | Round bar steel: 1mm ukuya 2000mm Intsimbi yesikwele: 10mm ukuya kwi-1000mm intsimbi Plate / sheet: 0.08mm ukuba 800mm Ububanzi: 10mm ukuya 1500mm I-Lenth: Singanikezela nayiphi na i-lenth ngokusekelwe kwimfuno yomthengi. Ukubumba: Iishafti ezineflanki / imibhobho / iityhubhu / i-slugs / iidonathi / iityhubhu / ezinye iimilo Iibhubhu: OD: φ4-410 mm, kunye nobukhulu bodonga ukusuka kwi-1-35 mm. |

| Unyango lobushushu | Ukuqheleka, ukufudumeza, ukufudumeza, ukucima, ukwenza lukhuni kunye nokuthambisa |

I-AWS E10015-D2 UKWENZIWA KWEKHEMICAL KUNYE NEEPROPERTIESL ZOMSHISHINI:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Okunye |

IIPROPATI ZOOMATSHINI:

| Iipropati | Iimeko | ||

| T (°C) | Unyango | ||

| Uxinzelelo (×1000kg/m3) | 7.7-8.03 | 25 |

|

| Umlinganiselo wePoisson | 0.27-0.30 | 25 |

|

| I-Elastic Modulus (GPA) | 190-210 | 25 |

|

| Amandla Okuqina (Mpa) | 1158 | 25 | i-oyile yacinywa, yacolwa kakuhle, ishushu kwi-425°C |

| Isivuno Amandla (Mpa) | 1034 | ||

| Ubude (%) | 15 | ||

| Ukunciphisa kwiNdawo (%) | 53 | ||

| Ukuqina (HB) | 335 | 25 | i-oyile yacinywa, yacolwa kakuhle, ishushu kwi-425°C |

| Iipropati | Iimeko | ||

| T (°C) | Unyango | ||

| I-Thermal Conductivity (W/mK) | 42.7 | 100 | |

| Ubushushu obubodwa (J/kg-K) | 477 | 50-100 | |

IIPROPATI ZOMZIMBA:

| Ubungakanani | Ixabiso | Iyunithi |

| Ukwandiswa kweThermal | 16 - 17 | e-6/K |

| I-Thermal conductivity | 16 - 16 | W/mK |

| Ubushushu obuthile | 500 - 500 | J/kg.K |

| Ubushushu obunyibilikayo | 1370 - 1400 | °C |

| Ubushushu benkonzo | 0 - 500 | °C |

| Ukuxinana | 8000 - 8000 | kg/m3 |

| Ukuxhathisa | 0.7 - 0.7 | Ohm.mm2/m |

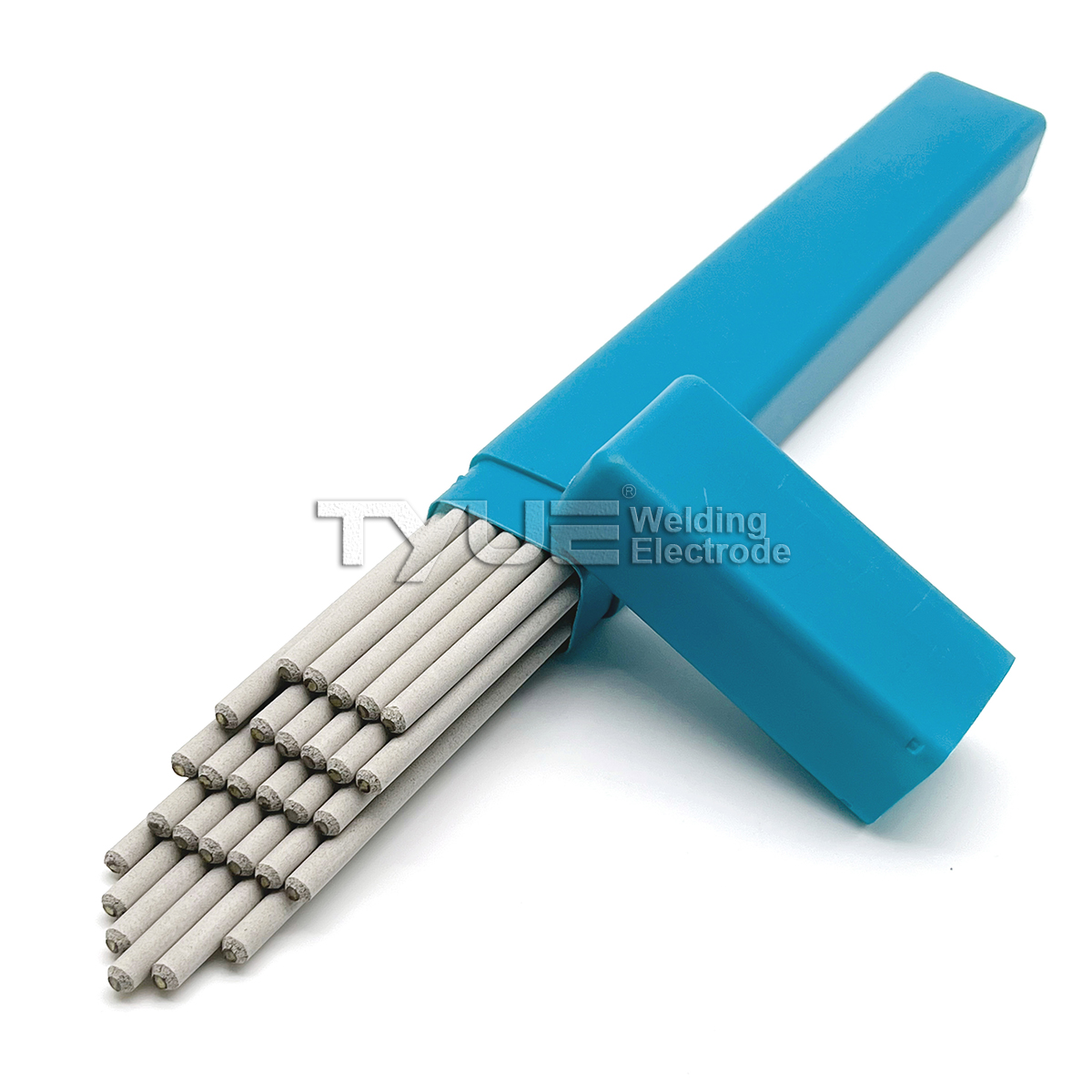

E7015-G Low Hydrogen Sodium Coating Welding Electrodes

INGCACISO:

Yintonga yentsimbi yokushisa ephantsi ene-sodium hydrogen coating ephantsi ene-nickel.Isikhundla esipheleleyo se-welding sinokuqhutywa ngokuqhagamshelwa kwe-dc reverse.Kwi -80°C weld metal isenayo ifuthe elihle lokuqina.

USEBENZISA:

I-Welded -80 ° C isebenza nge-1.5Ni isakhiwo sentsimbi.

ULWAKHIWO LWEMETALI OLUNDOQO:

| C | Mn | Si | Ni | S | P | |

| Umgangatho | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Uvavanyo | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

UKUSEBENZA KWEMETALI EDEPOSIWEYO:

| Amandla e-Tensile Rm (MPa) | Yield Strength Rel (MPa) | Elongation A (%) | -80°C Ixabiso leMpembelelo Akv (J) | |

| Umgangatho | ≥490 | ≥390 | ≥22 | ≥27 |

| Uvavanyo | 530 | 445 | 30 | 100 |

IREFENTIAL CURRENT (DC+):

| Ububanzi (mm) | 3.2 | 4.0 | 5.0 | |

| Ubude (mm) | 350 | 400 | 400 | |

| Okwangoku (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Ngokutsho GB E8515-G Ihambelana ne-AWS E12015-G |

Intshayelelo: I-E12015-G luhlobo lwe-electrode yensimbi ephantsi-i-alloy ephezulu kunye ne-low-hydrogen natrium yodidi lwe-coating.I-DCRP (iPolarity yangoku eReversed ngqo).I-welding yendawo yonke.

Usetyenziso: Isetyenziselwa ukuwelda izakhiwo zentsimbi ezisezantsi-ialloyi ezinamandla ezinamandla amalunga ne-830MPa.

Ukudityaniswa kwemichiza yentsimbi egciniweyo (%)

| Ukuqulunqwa kwemichiza | C | Mn | Si | S | P | Mo |

| Ixabiso lesiqinisekiso | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| Isiphumo ngokubanzi | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

IiPropati zeMechanical zeMetal eDiphozithiweyo

| Into yovavanyo | Rm(MPa) | Rel okanyeRp0.2(Mpa) | A(%) | KV2(J) |

| Ixabiso lesiqinisekiso | ≥830 | ≥740 | ≥12 | —(ubushushu obuqhelekileyo) |

| Isiphumo ngokubanzi | 860~950 | ≥750 | 12-20 | ≥27 |

Isiqulatho seHydrojeni esiDiphukayo kwiMetal eGcithiweyo: ≤5.0ml/100g(Chromatography)

UHlolo lwe-X-reyi yeRadiographic: ⅠIsidanga

IMIYALELO:

1.I-electrodes kufuneka ibhakwe phantsi kwe-350-400℃ iyure ngaphambi kokuba i-welding, ifakwe kwi-insulation can kwaye ifakwe ngokukhawuleza xa ifuneka.

2.Amabala akwi weld efana nomhlwa kufuneka asuswe, kwaye intsimbi kufuneka ifudunyezwe malunga ne-200℃.

I-3.I-Weld inokufudumala phantsi kwe-600-650 ℃ emva kwe-welding ukwenzela ukuphelisa uxinzelelo lwangaphakathi.