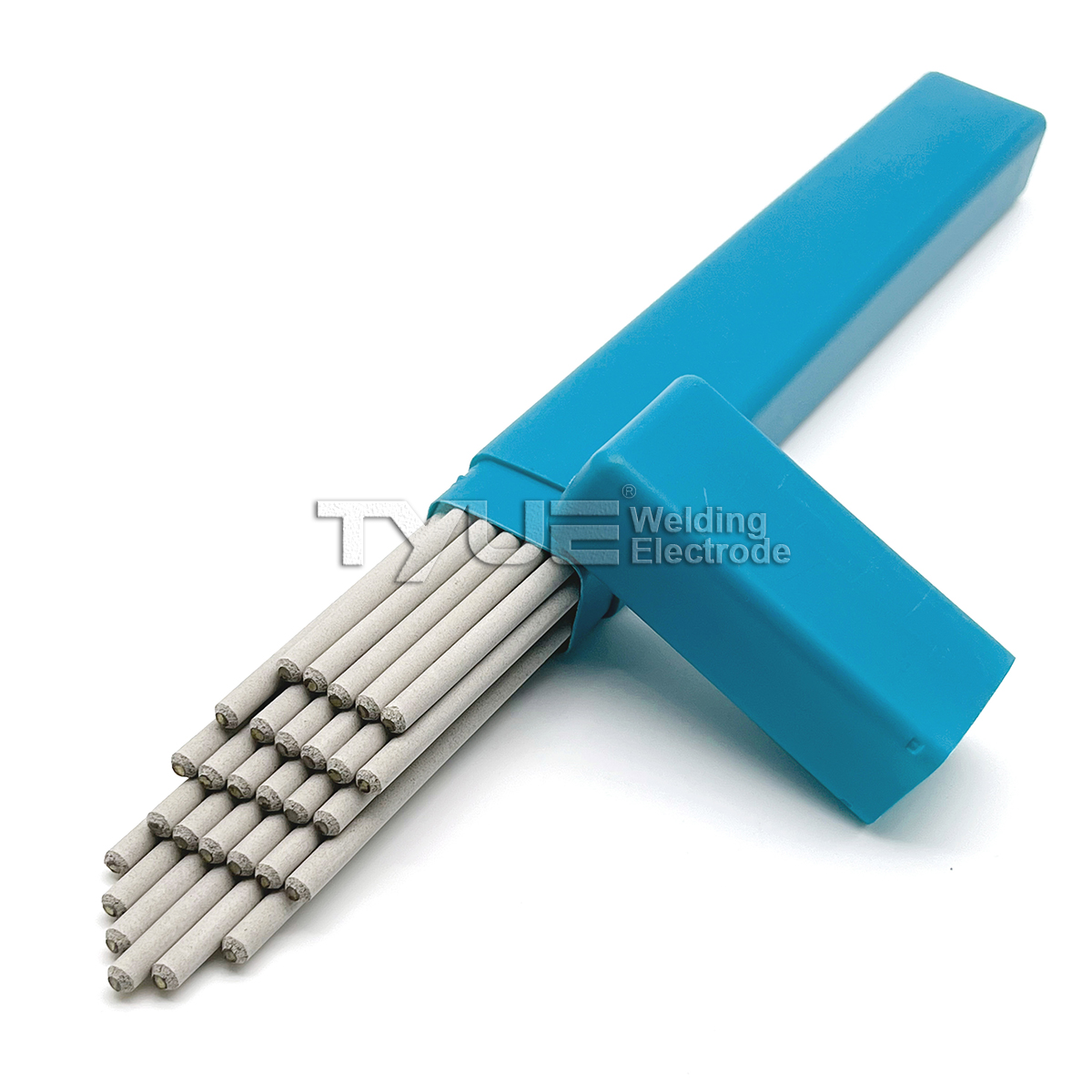

Ubushushu obuphantsiUkuwelda ngentsimbiI-electrode

W606Fe

I-GB/T E5518-C1

I-AWS A5.5 E8018-C1

Inkcazo: I-W606Fe yi-electrode yentsimbi enobushushu obuphantsi enomgubo wentsimbi kunye ne-hydrogen potassium coating ephantsi. Ingasetyenziselwa ukuwelda kuzo zonke iindawo nge-AC kunye ne-DC. Isinyithi esifakwe kwi-deposit sinokuqina okuhle kwi--60°C.

Isicelo: Isetyenziselwa ukuwelda intsimbi enobushushu obuphantsi efana ne-2.5Ni.

Ukwakheka kweekhemikhali zesinyithi esijiyiweyo (%):

| C | Mn | Si | Ni | S | P |

| ≤0. 12 | ≤1.25 | ≤0.80 | 2.00 ~ 2.75 | ≤0.020 | ≤0.025 |

Iimpawu zoomatshini zesinyithi esijijekileyo:

| Into yovavanyo | Tensile strength I-Mpa | Unikeze Amandla I-Mpa | Ukwandiswa % | Ixabiso lempembelelo (J) -60℃ |

| Iqinisekisiwe | ≥540 | ≥440 | ≥17 | ≥27 |

Umthamo we-hydrogen osasazekileyo kwisinyithi esigciniweyo: ≤6.0mL/100g (indlela ye-glycerin) okanye ≤10mL/100g (indlela ye-mercury okanye i-gas chromatography)

Ukuhlolwa kwe-X-ray: Ibanga loku-1

I-current ecetyiswayo:

| (mm) Ububanzi bentonga | 3.2 | 4.0 | 5.0 |

| (A) Ukuwelda kwangoku | 90 ~ 120 | 140 ~ 180 | 180 ~ 210 |

Isaziso:

1. I-electrode kufuneka ibhakwe iyure e-1 kwi-350℃ ngaphambi kokuba kusetyenziswe i-welding;

2. Kubalulekile ukucoca umhlwa, isikali seoyile, amanzi, kunye nokungcola kwiindawo zokuwelda ngaphambi kokuba uwelda.