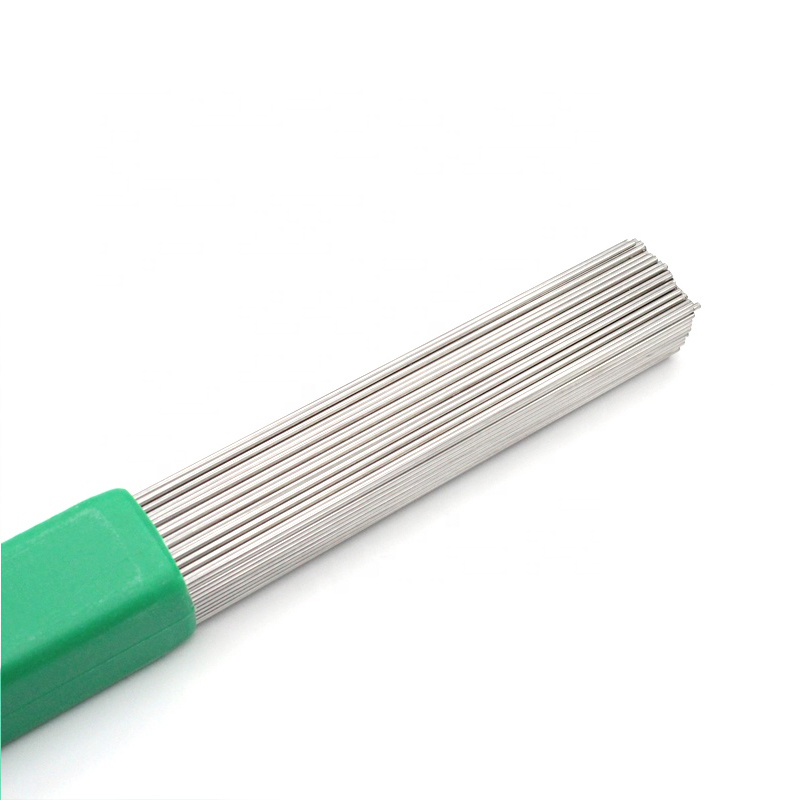

I-ER5183 ifanelekile kwi-MIG yokuwelda i-aluminium magnesium alloy apho kufuneka amandla aphezulu okutsalwa kwaye ukuba isiseko sesinyithi yi-5083 okanye i-5654 amandla okutsalwa ebeya kuba phezulu kakhulu. Isetyenziswa kakhulu ekudibaniseni izakhiwo ze-aluminium magnesium alloy zeenqanawa, amaqonga aselunxwemeni, iilocomotives kunye neenqwelo, iimoto, izikhongozeli, iinqanawa ezi-cryogenic njalo njalo. Isinyithi sayo esidityanisiweyo sinokumelana okuhle nokugqwala kwe-brine.

Indawo yokuWelda: F, HF, V

Uhlobo lwangoku: DCEP

ISAZISO:

Ukugcina ipakethe yocingo ikwimeko entle ngaphambi kokuyidibanisa.

Zombini iindawo eziza kudityaniswa nge-weldment kunye nocingo mazicocwe zisuse ukungcola okubangelwa yi-oyile, i-oxide coating, ukufuma njalo njalo.

Ukuze i-weld ibonakale kakuhle, kuyimfuneko ukuyifudumeza isiseko sentsimbi ukuya kwi-100℃-200℃ ngaphambi kokuba uyi-welding ukuba ubukhulu bayo buyi-10mm nangaphezulu.

Kungcono ukubeka ipleyiti engaphantsi komhlaba phantsi kwendawo yokuwelda ukuze kuxhaswe isinyithi esinyibilikisiweyo ukuze kuqinisekiswe ukuba intsimbi ingena ngokupheleleyo kwindawo yokuwelda.

Ngokwendawo yokuwelda kunye nobukhulu besiseko sentsimbi, kufuneka kukhethwe igesi eyahlukeneyo yokukhusela, efana ne-100%Ar, 75%Ar+25%He, 50%Ar+50%He, njl.

Imiqathango yokuwelda ekhankanyiweyo apha ngasentla yenzelwe ukubhekisa kuphela kwaye kungcono ukwenza isiqinisekiso senkqubo yokuwelda ngokweprojekthi ngaphambi kokuba uyifake kwi-welding esemthethweni.

ER5183 UKWAKHIWA KWEEKHEMIKHALI KWESINYITHI ESIGCINIWEYO (%):

| SI | FE | CU | MN | MG | CR | ZN | TI | AI | BE | |

| Umgangatho | ≤0.40 | ≤0.40 | ≤0.10 | 0.50-10 | 4.3-52 | 0.05-0.5 | ≤0.25 | ≤0.15 | Ibhalansi | ≤0.0003 |

| Okuqhelekileyo | 0.08 | 0.12 | 0.006 | 0.65 | 4.75 | 0.130 | 0.005 | 0.080 | Ibhalansi | 0.0001 |

IIPROPATI ZOOMATSHINI ZESIMBI ESIGCINIWEYO (AW):

| I-RM YAMANDLA OKUTHAMBA (i-MPA) | I-REL YAMANDLA EMVELISO (MPA) | UKULONDOLOZWA A4 (%) | |

| Okuqhelekileyo | 280 | 150 | 18 |

Ubungakanani kunye neKhona ecetyiswayo ye-MIG (DC+):

| Ububanzi bocingo lokuwelda (MM) | 1.2 | 1.6 | 2.0 |

| Umsinga wokuWelda (A) | 180-300 | 200-400 | 240-450 |

| I-Welding Voltage (V) | 18-28 | 20-20 | 22-34 |

Ubungakanani kunye ne-current ecetyiswayo ye-TIG (DC¯):

| Ububanzi bocingo lokuwelda (MM) | 1.6-2.5 | 2.5-4.0 | 4.0-5.0 |

| Umsinga wokuWelda (A) | 150-250 | 200-320 | 220-400 |

I-Wenzhou Tianyu Electronic Co., Ltd. yasekwa ngo-2000. Besisenza ushishino lokuvelisa ii-electrode zokuwelda, iintonga zokuwelda, kunye nezinto ezisetyenziswayo zokuwelda kangangeminyaka engaphezu kwama-20.

Iimveliso zethu eziphambili ziquka ii-electrode zokuwelda zentsimbi engagqwaliyo, ii-electrode zokuwelda zentsimbi yekhabhoni, ii-electrode zokuwelda ze-alloy ephantsi, ii-electrode zokuwelda eziphezu komhlaba, ii-electrode zokuwelda ze-nickel kunye ne-cobalt alloy, ii-wire welding zentsimbi emild kunye ne-low alloy, ii-wire welding zentsimbi engagqwaliyo, ii-wire ze-flux cored ezikhuselwe yigesi, ii-wire welding ze-aluminium, ii-inferiored arc welding. ii-wire, ii-wire welding ze-nickel kunye ne-cobalt alloy, ii-wire welding ze-brass welding, ii-wire welding ze-TIG kunye ne-MIG, ii-electrode ze-tungsten, ii-electrode ze-carbon gouging, kunye nezinye izixhobo zokuwelda kunye nezinto ezisetyenziswayo.