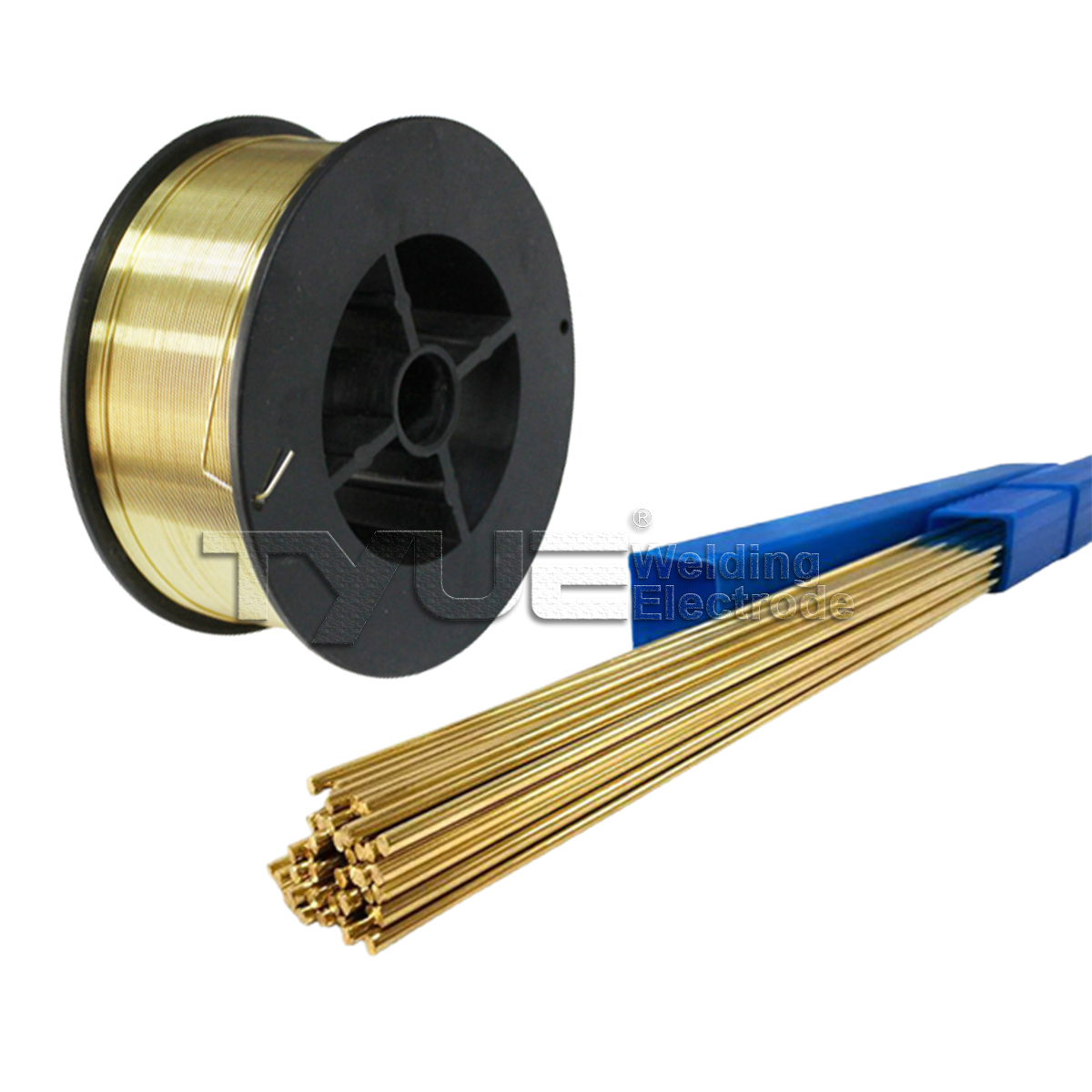

I-Aluminiyam ye-ERCuAl-A1 yobheduUcingo lokuWeldayi-alloy ye-aluminium bronze engenasinyithi, efumaneka kwi-spooled wire kunye ne-36” bare-filler metal rod ukuze isetyenziswe kwiinkqubo zokuwelda ze-gas metal-arc kunye ne-gas tungsten-arc ngokulandelanayo.

I-Aluminiyam ye-ERCuAl-A1 yobheduUcingo lokuWeldaIidipozithi zisetyenziselwa ikakhulu ukugquma iibheringi kunye neendawo ezingagugiyo ezifuna ubunzima obumalunga ne-125 BHN kunye nokumelana nokugqwala ngakumbi kumanzi anetyuwa, iityuwa zesinyithi, kunye nee-asidi ezininzi ezisetyenziswa rhoqo kumanqanaba ahlukeneyo kunye namaqondo obushushu. Le alloy ayikhuthazwa ukuba idipozithi idipozithi idipozithi kuba ayinalo utyekelo lokuba mfutshane.

I-ERCuAl-A1 Aluminium Bronze Welding Wire I-Aluminium Bronze Welding Wire Izicelo ze-Aluminium Bronze Wire ziquka iityhubhu sheets, izihlalo zeevalvu, ii-pickling hooks, ii-impellers, izityalo zeekhemikhali, kunye nee-pulp mills.

I-ERCUAL-A1 ALUMINUM BROSZE WELING WIRE IIPROPERTI ZOKWENZIWA KWEZINTO EZIPHAMBILIYO NEZINOMKHANIKA

| Izinto eziqinileyo-Ubushushu | 1030℃ |

| Uxinano | 7.7kg/dm³ |

| Ukwandiswa | 40-45% |

| Ulwelo-Ubushushu | 1040℃ |

| Tensile strength | 380-450N/mm² |

| Ubunzima bukaBrinell | 100HB |

UKUPAKISHA IINTYAYA ZOKWENDLELA ZE-ALUMINUM ZE-ERCUAL-A1

| I-MIG | Ububanzi | 0.8 – 2.0mm | Ukupakisha | D100mm D200mm D300mm | Ubunzima | 1kg/5kg/12.5kg/13.6kg/15kg |

| 0.030″-5/64″ | 2lb/10lb/27lb/ 30lb/33lb | |||||

| I-TIG | Ububanzi | 1.6 – 6.4mm | Ubude | 457mm / 914mm | Ukupakisha | 5kg/ibhokisi 25kg/ibhokisi 10kg/iphakheji yeplastiki |

| 1/16″ – 1/4″ | 18″ / 36″ | 10lb/ibhokisi 50lb/ibhokisi 10kg/iphakheji yeplastiki |

Nceda uqaphele: Iimveliso ze-spools zomthi ezingama-500lb ziyafumaneka xa uzicelile.

I-ERCUAL-A1 ALUMINUM BRONZE WELING WELDING WIRE (%)

| Umgangatho | I-ISO24373 | GB/T9460 | GB/T9460 | I-BS EN14640 | I-AWS A5.7 | I-DIN 1733 |

| Iklasi | I-Cu6100 | I-SCu6100 | I-SCu6100A | I-Cu6100 | C61000 | 2.0921 |

| I-alloy | I-CuAl7 | I-CuAl7 | I-CuAl8 | I-CuAl8 | I-ERCuAl-A1 | SG-CuAl8 |

| Cu | ibhal. | ibhal. | ibhal. | ibhal. | ibhal. | ibhal. |

| Al | 6.0-8.5 | 6.0-8.5 | 7.0-9.0 | 6.0-9.5 | 6.0-8.5 | 7.5-9.5 |

| Fe | – | – | ubuninzi 0.5 | 0.5 | – | ubuninzi 0.5 |

| Mn | 0.5 | ubuninzi 0.5 | ubuninzi 0.5 | 0.5 | 0.5 | ubuninzi 1.0 |

| Ni | – | – | ubuninzi 0.5 | 0.8 | – | ubuninzi 0.8 |

| P | – | – | – | – | – | – |

| Pb | 0.02 | – | ubuninzi 0.02 | 0.02 | 0.02 | ubuninzi 0.02 |

| Si | 0.2 | ubuninzi 0.1 | ubuninzi 0.2 | 0.2 | 0.1 | ubuninzi 0.2 |

| Sn | – | – | ubuninzi 0.1 | – | – | – |

| Zn | 0.2 | ubuninzi 0.2 | ubuninzi 0.2 | 0.2 | 0.2 | ubuninzi 0.2 |

| enye | 0.4 | ubuninzi 0.5 | ubuninzi 0.2 | 0.4 | 0.5 | ubuninzi 0.4 |

I-Wenzhou Tianyu Electronic Co., Ltd. yasekwa ngo-2000. Besisenza ushishino lokuvelisa ii-electrode zokuwelda, iintonga zokuwelda, kunye nezinto ezisetyenziswayo zokuwelda kangangeminyaka engaphezu kwama-20.

Iimveliso zethu eziphambili ziquka ii-electrode zokuwelda zentsimbi engagqwaliyo, ii-electrode zokuwelda zentsimbi yekhabhoni, ii-electrode zokuwelda ze-alloy ephantsi, ii-electrode zokuwelda eziphezu komhlaba, ii-electrode zokuwelda ze-nickel kunye ne-cobalt alloy, ii-wire welding zentsimbi emild kunye ne-low alloy, ii-wire welding zentsimbi engagqwaliyo, ii-wire ze-flux cored ezikhuselwe yigesi, ii-wire welding ze-aluminium, ii-inferiored arc welding. ii-wire, ii-wire welding ze-nickel kunye ne-cobalt alloy, ii-wire welding ze-brass welding, ii-wire welding ze-TIG kunye ne-MIG, ii-electrode ze-tungsten, ii-electrode ze-carbon gouging, kunye nezinye izixhobo zokuwelda kunye nezinto ezisetyenziswayo.