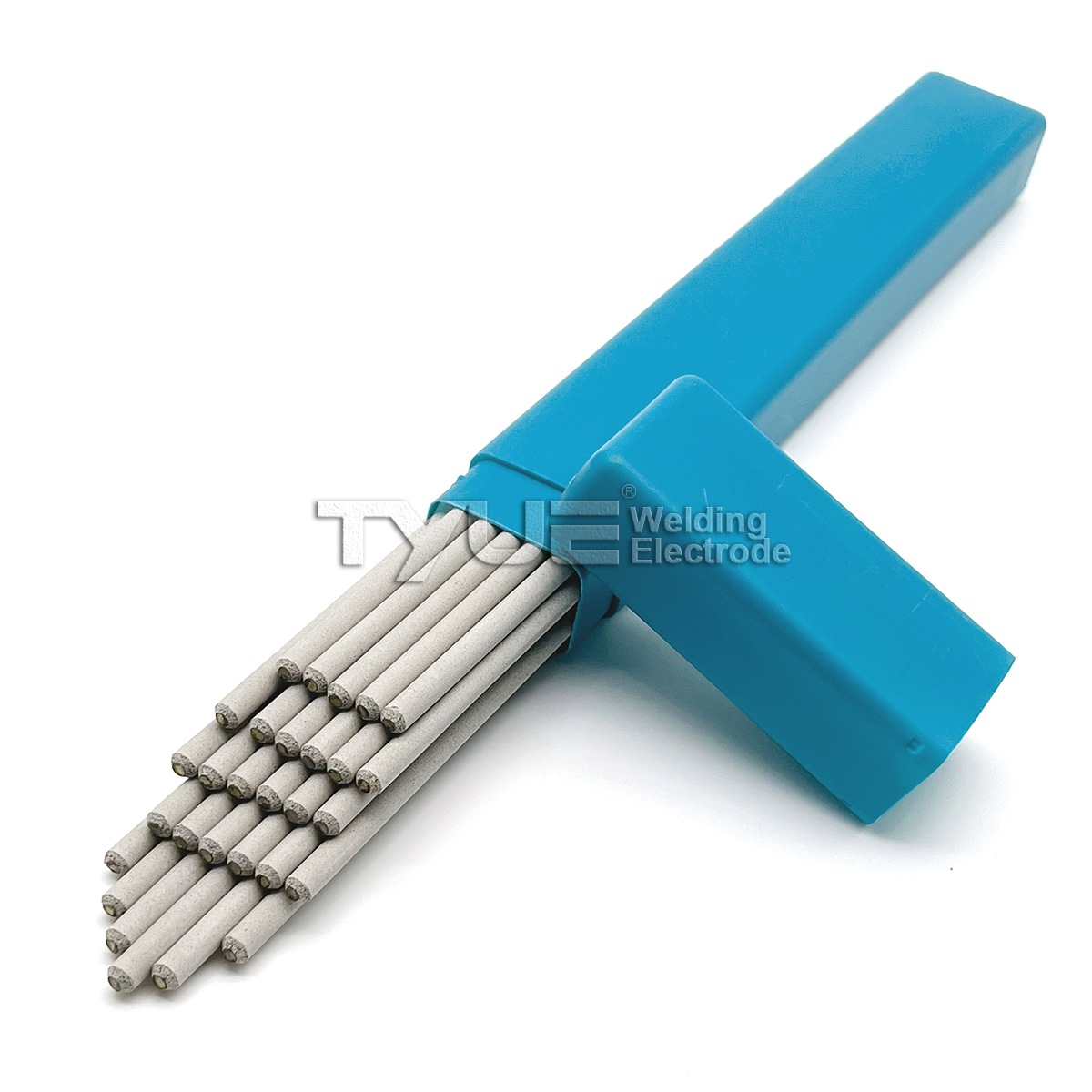

Ukuwelda kweNsimbi EngagqwaliyoI-electrode

AF2594-16

I-AWS A5.4 E2594-16

Inkcazo: I-AF2594-16 yi-electrode yentsimbi engenasici ephindwe kabini ene-nitrogen ekhabhoni ephantsi kakhulu ene-titanium-calcium coating. Ingasetyenziselwa zombini i-AC kunye ne-DC. I-PRE (ixabiso elilinganayo lokumelana nemigodi okanye i-pitting index) ≥ 40, isinyithi esigciniweyo sinokuxhathisa okuhle kokuqhekeka kobushushu. Ngenxa yomxholo ophantsi wekhabhoni kunye nomlinganiselo othile we-molybdenum kunye ne-nitrogen, isinyithi esigciniweyo sinokuxhathisa okuhle kokuqhekeka kwemigodi kunye nokuqhekeka koxinzelelo lokuqhekeka.

Ukusetyenziswa: Isetyenziswa kakhulu ekudibaniseni uhlobo olufanayo lwentsimbi engagqwaliyo ye-duplex kwimizi-mveliso yeoyile engaselunxwemeni, igesi yendalo kunye ne-petrochemical, efana ne-00Cr25Ni7Mo4N, njl.

Ukwakheka kweekhemikhali zesinyithi esijiyiweyo (%):

| C | Mn | Si | Cr | Ni | Mo | N | Cu | S | P |

| ≤0.04 | 0.5 ~ 2.0 | ≤1.00 | 24.0 ~ 27.0 | 8.0 ~ 10.5 | 3.5 ~ 4.5 | 0.20 ~ 0.30 | ≤0.75 | ≤0.030 | ≤0.040 |

Iimpawu zoomatshini zesinyithi esijijekileyo:

| Into yovavanyo | Tensile strength I-Mpa | Ukwandiswa % |

| Iqinisekisiwe | ≥760 | ≥15 |

I-current ecetyiswayo:

| Ububanzi bentonga (IsiNgesi)mm) | 2.5 | 3.2 | 4.0 | 5.0 |

| Ukuwelda kwangoku (IsiNgesi)A) | 50 ~80 | 80 ~ 120 | 120 ~ 150 | 150 ~ 200 |

Isaziso:

1. I-electrode mayibhakwe iyure e-1 malunga nama-250℃ ngaphambi kokuba isebenze nge-welding;

2. Kubalulekile ukucoca umhlwa, isikali seoyile, amanzi, kunye nokungcola kwiindawo zokuwelda ngaphambi kokuba uwelda.

I-Wenzhou Tianyu Electronic Co., Ltd. yasungulwa ngo-2000. Besibandakanyeka kwimveliso yei-electrode yokuweldas, iintonga zokuweldakunyeizinto ezisetyenziswayo zokuweldakangangeminyaka engaphezu kwama-20.

Iimveliso zethu eziphambili ziquka intsimbi engagqwaliyoi-electrode yokuweldaii-electrode zokuwelda zentsimbi yekhabhoni, ii-electrode zokuwelda ze-alloy ephantsi, ii-electrode zokuwelda eziphezu komhlaba, ii-electrode zokuwelda ze-nickel kunye ne-cobalt alloy, ii-wire welding zentsimbi emild kunye ne-low alloy, ii-wire welding zentsimbi engatyiwayo, ii-wire ze-flux cored ezikhuselwe yigesi, ii-wire welding ze-aluminium, i-submerged arc welding. ii-wire, ii-wire welding ze-nickel kunye ne-cobalt alloy, ii-wire welding ze-brass, ii-wire welding ze-TIG kunye ne-MIG, ii-electrode ze-tungsten, ii-electrode ze-carbon gouging, kunye nezinye izixhobo zokuwelda kunye nezinto ezisetyenziswayo.