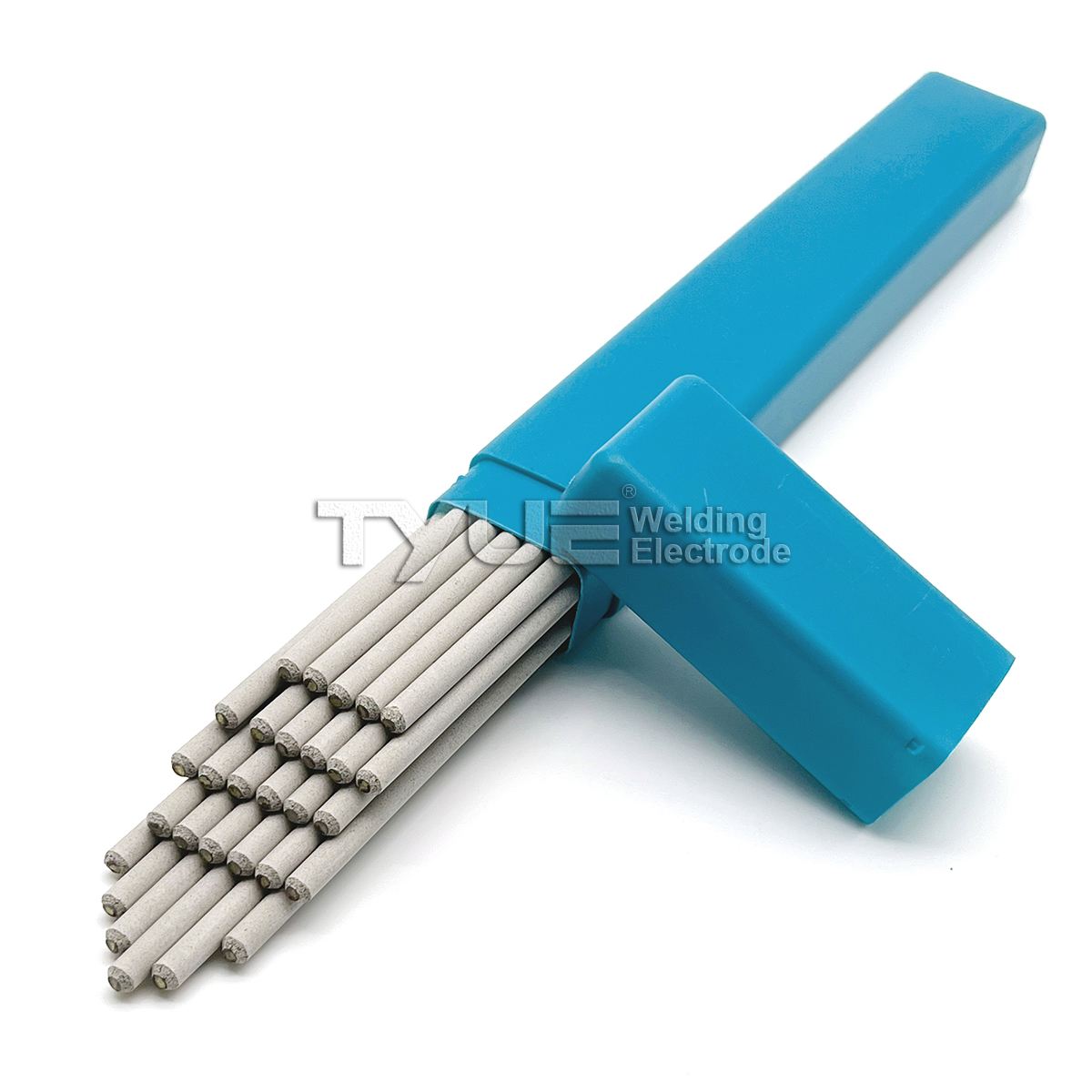

Ingxubevange ephantsiSteel WeldingI-Electrode

J607

I-GB/T E6015-D1

AWS E9015-D1

Inkcazo: I-J607 i-alloy ephantsi ye-electrode yensimbi ene-low-hydrogen sodium coating.Sebenzisa i-DCEP (i-electrode echanekileyo yangoku), kwaye inokudityaniswa kuzo zonke izikhundla.

Isicelo: Isetyenziselwa i-welding medium carbon steel kunye ne-alloy low-alloy high-strength steel structures of the strength ehambelanayo, njenge-Q420, njl.

Ukwakhiwa kweekhemikhali zentsimbi edibeneyo(%):

| C | Mn | Si | Mo | S | P |

| ≤0.12 | 1.25 ~ 1.75 | ≤0.60 | 0.25 ~ 0.45 | ≤0.035 | ≤0.035 |

Iimpawu zobuchwephesha bentsimbi ye-weld:

| Into yovavanyo | Tensile strength Mpa | Unikeze Amandla Mpa | Elongation % | Ixabiso lempembelelo (J) -30℃ |

| Iqinisekisiwe | ≥590 | ≥490 | ≥15 | ≥27 |

| Ivavanyiwe | 620 ~ 680 | ≥500 | 20 ~ 28 | ≥27 |

Ukusasazwa kwe-hydrogen umxholo wesinyithi ogciniweyo: ≤4.0mL/100g (indlela yeglycerin)

Ukuhlolwa kwe-X-reyi: Ibanga

yangoku eCetyisiweyo:

| (mm) Intonga yobubanzi | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | 5.8 |

| (A) I-Welding yangoku | 60 ~ 80 | 70 ~ 90 | 90 ~ 120 | 140 ~ 180 | 170 ~ 210 | 210 ~ 260 |

Isaziso:

1. I-electrode kufuneka ibhakwe ngeyure eli-1 kwi-350 ℃ ngaphambi kokusebenza kwe-welding;

2. Kubalulekile ukucoca umhlwa, isikali se-oyile, amanzi, kunye nokungcola kwiindawo zokuwelda phambi kokuba udibanise;

3. Sebenzisa umsebenzi omfutshane we-arc xa udibanisa.Umzila we-welding emxinwa ufanelekile.