IZICELO:

I-Welding ye-9% Cr-1% Mo steels kunye ne-9% Cr - 2% Mo steels ezisetyenziselwa amandla ombane kunye nesitya soxinzelelo oluphezulu.

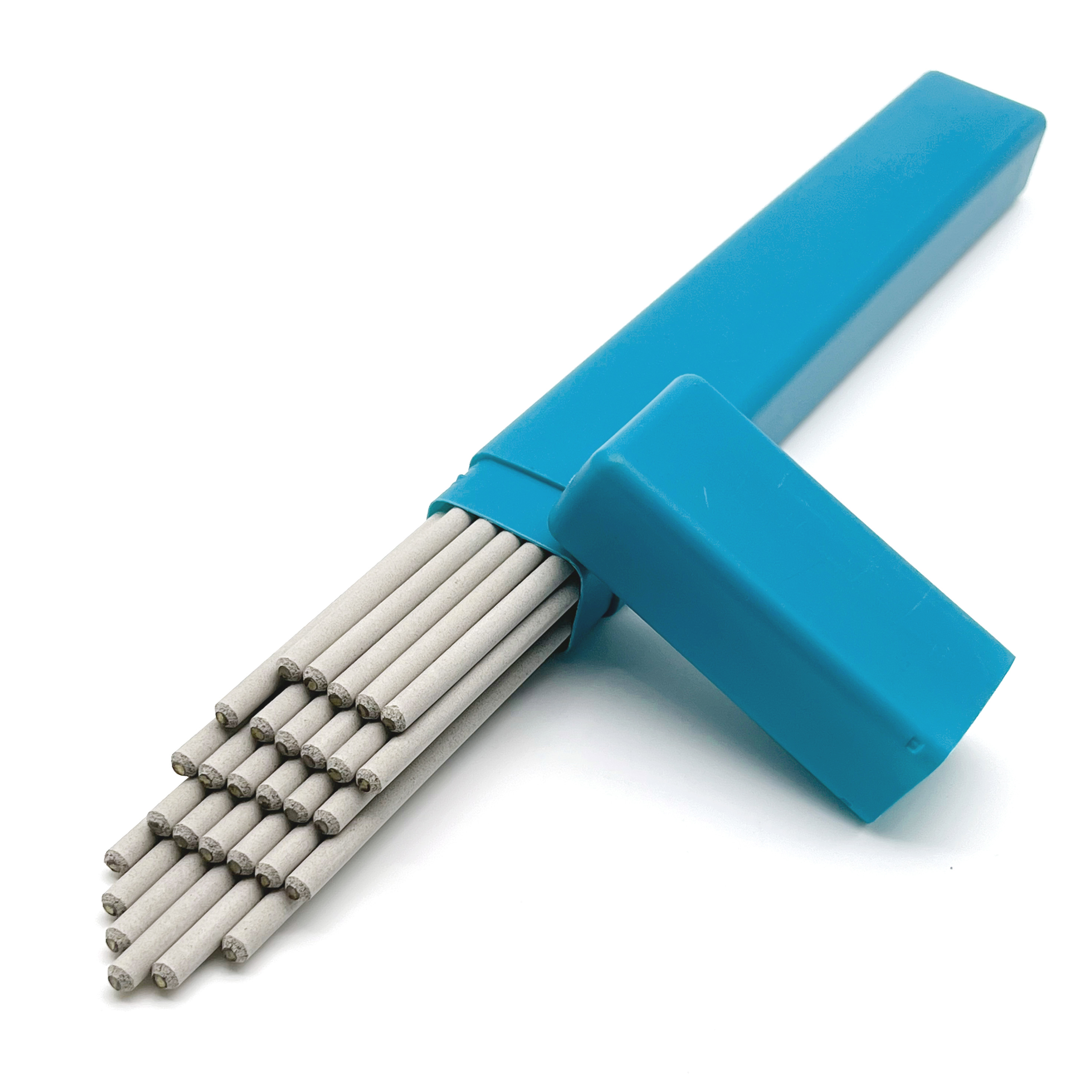

INKCAZELO:

I-PA-8016-B8 yi-electrode ephantsi ye-hydrogen enentsimbi ye-weld equkethe i-9% Cr-1% Mo.Yenzelwe ubushushu obuphezulu bentsimbi kunye neentsimbi zeenkonzo ze-hydrogen ezishushu, ngakumbi kwishishini lepetrochemical.I-electrode inokuvunywa ngenxa yokuqina kwayo okuphezulu, ukuqina okuhle kunye nokumelana nobushushu obukhulu.

AMANQAKU OKUSETYENZISWA:

1. Yomisa i-electrodes kwi-350-400 ° C malunga neyure enye ngaphambi kokusetyenziswa kwaye ugcine i-electrodes kwi-100-150 ° C emva kokumisa ingqwalasela yokugcina kude nomswakama.

2. Yamkela indlela yenyathelo lokubuyela umva okanye ubethe i-arc kwipleyiti encinci yentsimbi elungiselelwe le njongo ethile ukuthintela imingxuma yokuvuthela kwi-arc ukuqala.

3. Gcina i-arc imfutshane kangangoko.

4. Ukufudumala kwi-100-150 ° C.Iqondo lobushushu eliza kusetyenziswa liyahluka ngokuhambelana nobungqingqwa bepleyiti kunye nohlobo lwentsimbi ekufuneka idityaniswe.

5. Nika ingqalelo ukuba ungagqithisi igalelo elifanelekileyo lobushushu kuba ubushushu obugqithisileyo bubangela ukuwohloka kwamaxabiso empembelelo kunye namandla esivuno sentsimbi yeweld.

IV.UHLANGANISO LWEMETALI YE-WELD (%):

| C | Si | Mn | Cr | Mo |

| 0.06 | 0.42 | 0.68 | 9.38 | 1.05 |

V. IIPROPATI EZIQHELEKILEYO ZOMCEKANI WE-WELD METALI:

| Amandla Okuqina N/mm2(Ksi) | Inqaku leSivuno N/mm2 (Ksi) | Elongation % | PWHT |

| 705 (102) | 560 (81) | 24 | 740°C x 1 iyure |

VI.IINDAWO ZOKUSHISA: ZONKE IINDAWO

VII.UBUKHULU KUNYE OKUCETYIWEYO UDIDI OLWAKUMVA (AC/DC+):

| Ububanzi (mm) | 2.5 | 3.2 | 4.0 | 5.0 | |

| Ubude (mm) | 350 | 350 | 400 | 400 | |

| Ampere | Umcaba | 55 - 85 | 90 - 130 | 130 - 180 | 180 - 240 |

| V & OH | 50 - 80 | 80 - 115 | 110 - 170 | 150 - 200 |